Latest News

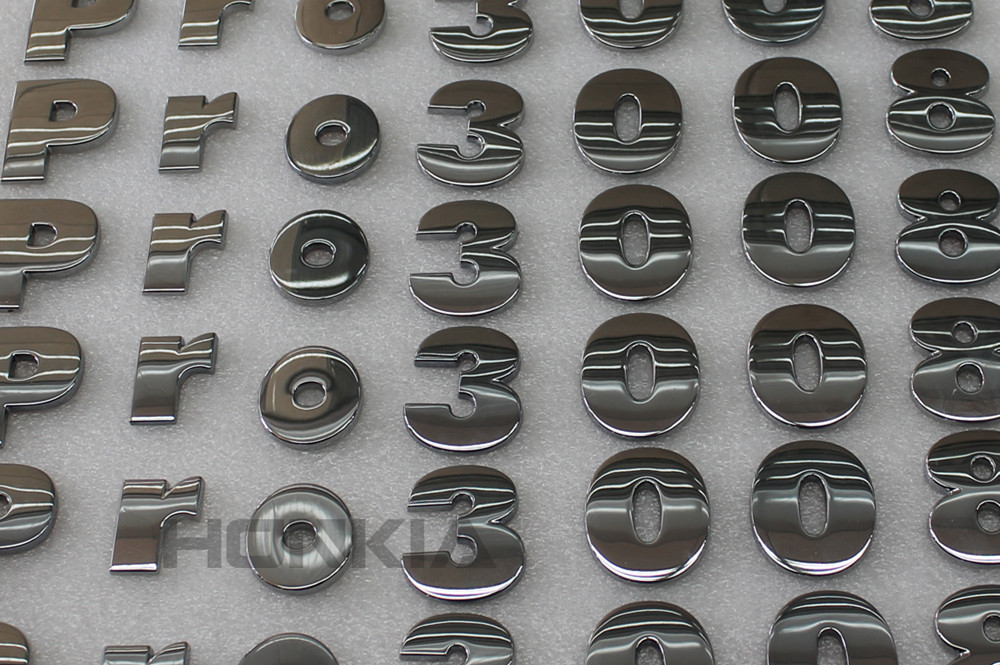

- Rapid Prototype Manufacturing in ChinaSource: Honkia Published: 2016-05-23 Views: 3212

-

Chinese prototype manufacturing originated in the early 1990s, at that time the prototypes were made completely by hands and tools because of the lagging technologies and weak industrial design in China, this was why even today some Chinese prototype makers were still accustomed to call prototype “Hand Model” that meant the model was made by hands. Therefore in that period the prototyping materials and accuracy were very limited as well as the surface finishing, and it was common to use one month to finish a prototype manufacturing.

In the middle of 1990s, with introduction and application of CNC (Computerized Numerical Control) technology for rapid prototype manufacturing in China, more and more prototype manufacturers gradually used CNC machining instead of hand making for tighter tolerance, more material options and higher efficiency, this not only strengthened the prototyping ability, also decreased the prototyping cost as well as the lead time. Since then, China’s rapid prototyping gone on the way of fast developing and wide application.

At the beginning of 2000s, more and more Chinese brands of CNC machines were developed and used for production, some of them had strong machining capabilities of high precision and wide material available, this gradually lowered the price of CNC machines and advanced the wide application of this technology at prototype factories in China. At that time, CNC machining and vacuum casting became the main rapid prototype manufacturing processes in China. Meanwhile, few China prototype factories invested and introduced SLA (stereolithography) process, and the news of 3D Printing technology occasionally appeared in China's media.

In the early 2010s, with fast development of Additive Manufacturing technologies around the world and its patent expiration, new more rapid prototyping technologies were applied in China, such as SLS (Selective Laser Sintering), FDM (Fused Deposition Modeling), LOM (Laminated Object Manufacturing), 3D Printing, etc. and 3D Printing had been the hot topic in general public with the news of 3D Printed car, house, mobile phone and something else presented in media, it aroused more and more people's big interest and strong attention in China, and some of them related it to the third industrial revolution.

Right now, CNC machining, vacuum casting and SLA were the three main prototype manufacturing processes in China though some western AM technology companies were developing their Chinese market for some time, while costly AM equipment, material and daily maintenance were the big challenge of this technology's wide application in China, cheap and target material were still the big advantages of CNC machining for prototype manufacturing, nearly 70% prototypes were CNC machined at Chinese prototype factories.

In the near predictable future, CNC machining would be still the first option for prototype manufacturing in China unless AM technologies or other ones could replace its advantages, at this time maybe it was really the age of Third Industrial Revolution.

Reaction Injection Molded Enclosure Parts

Reaction Injection Molded Enclosure Parts Rapid Low Volume Aluminum Prototypes

Rapid Low Volume Aluminum Prototypes