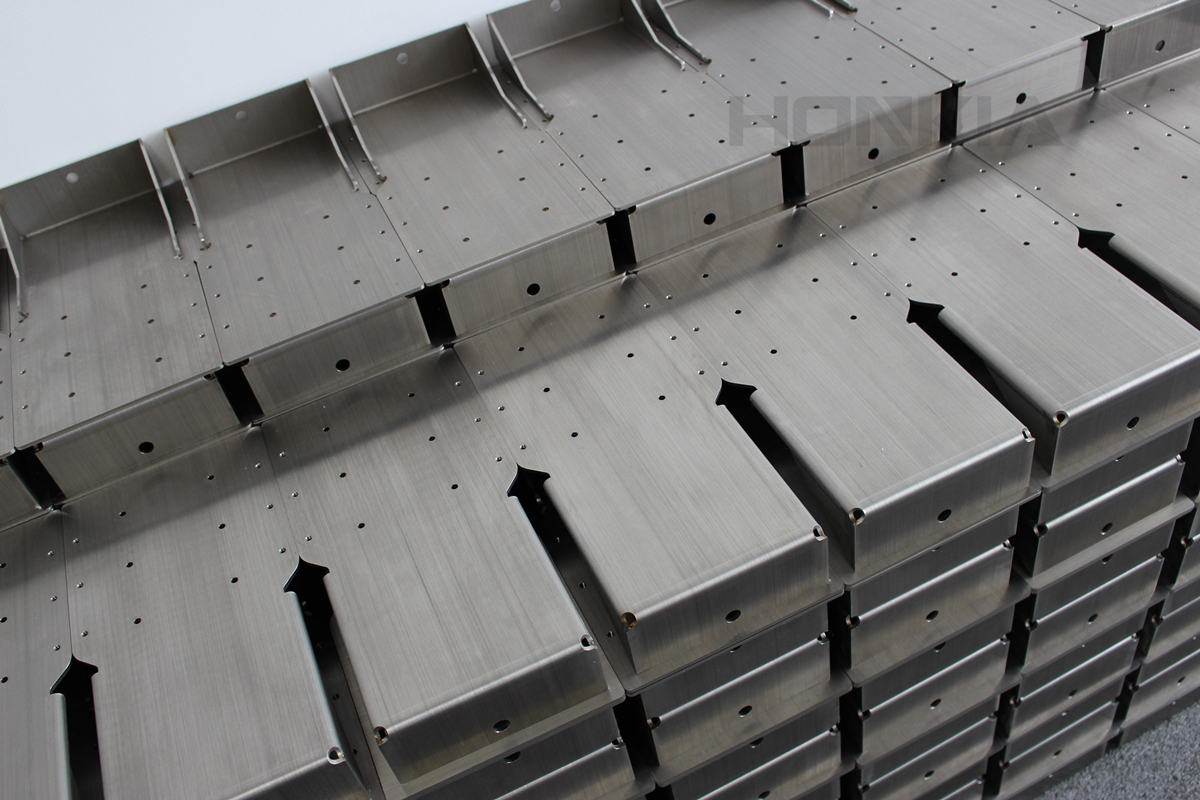

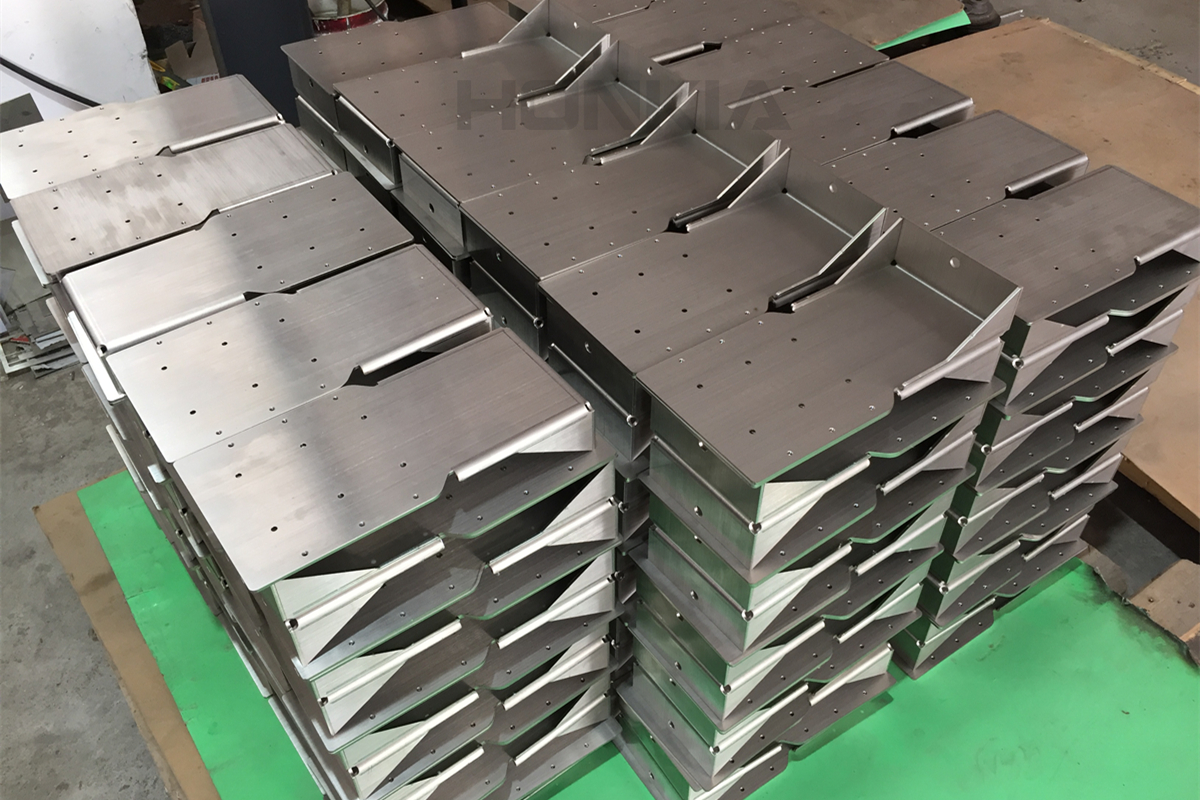

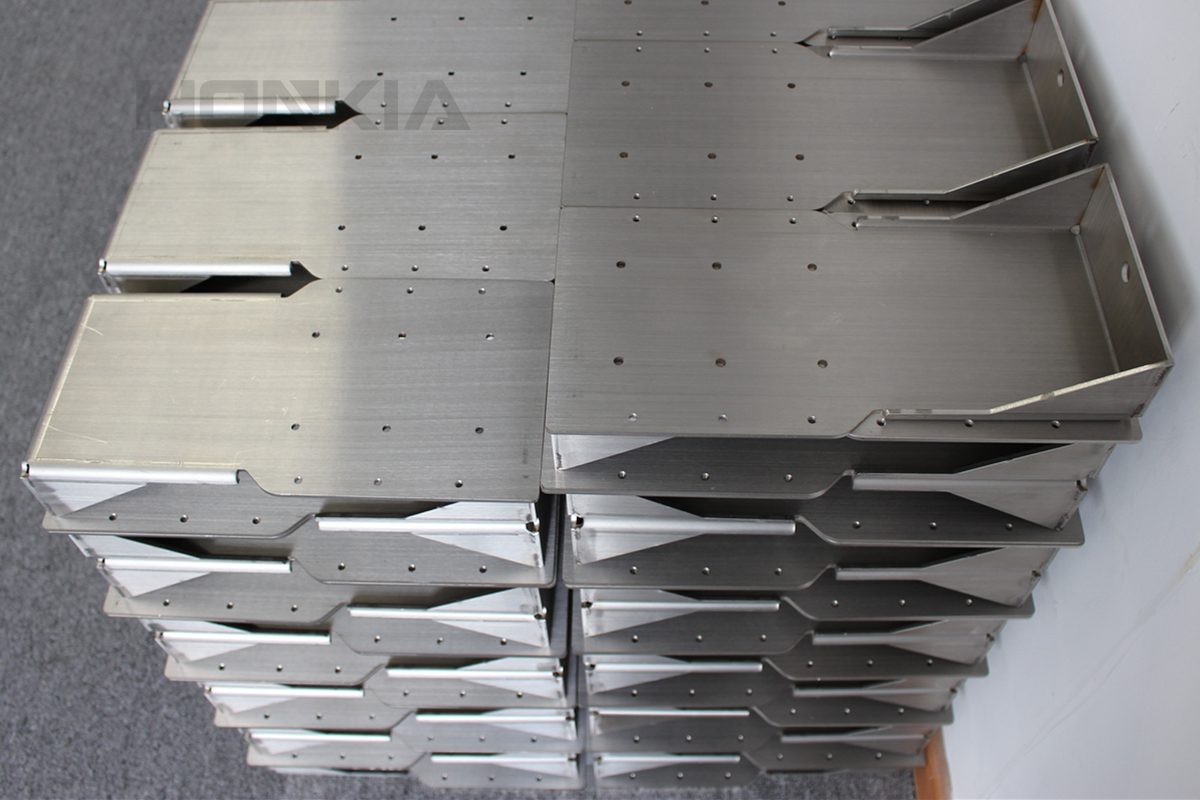

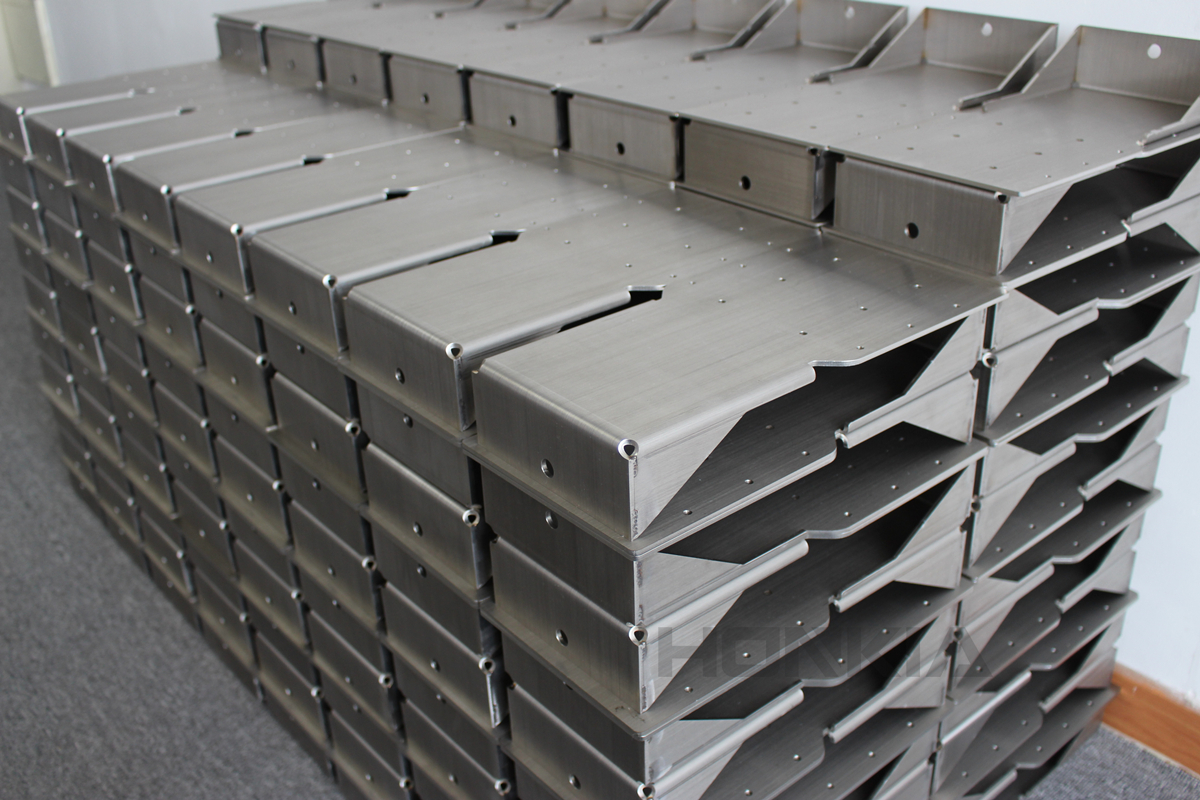

High Precision Sheet Metal Parts

Project Overview:Material: Stainless Steel 304 (SS 304), Thickness 3.5 mm, Brushed

Manufacturing Process: Laser Cutting & Bending, Welding

Surface Finishing: Deburring, Threading M5, Sanding

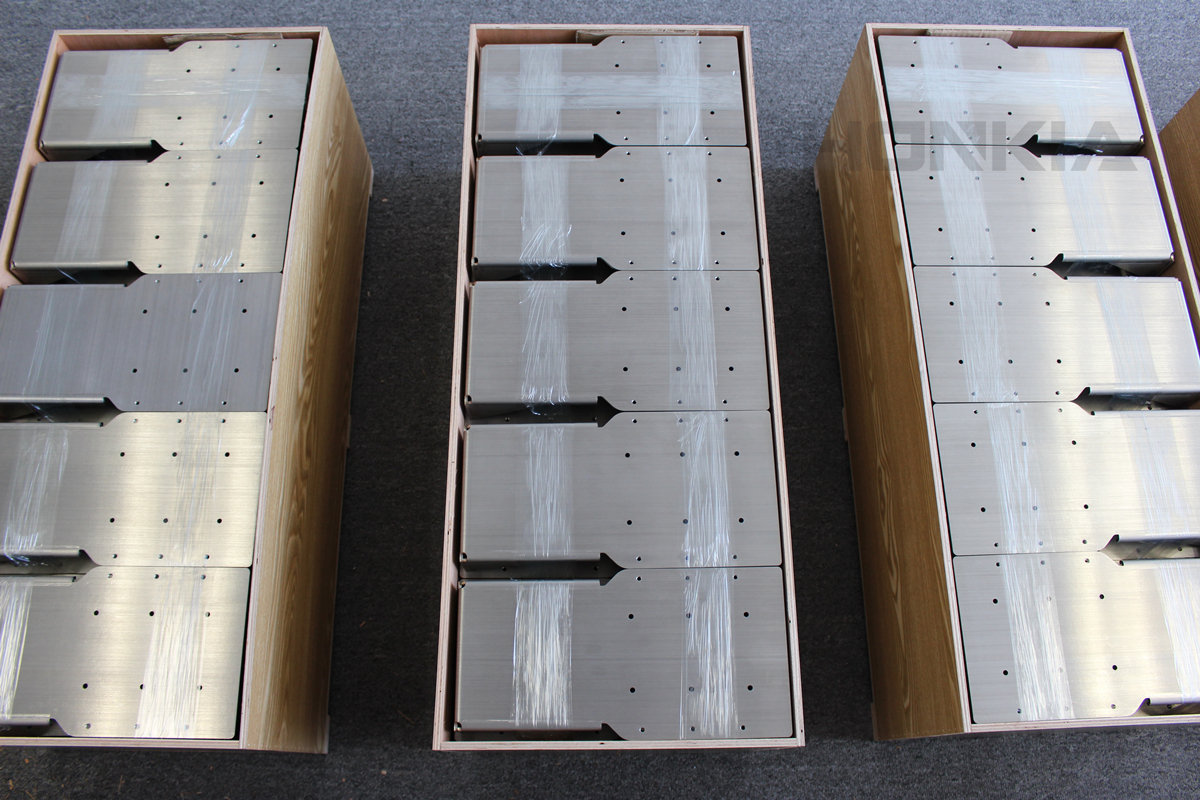

Quantity: 345 Units

Lead Time: 18 Days

Customer was from Canada and ordered those sheet metal parts for their mechanical systems. Rapid prototype prior to low volume production was made to test the manufacturing capability, particularly bending tolerance.

- Precision laser cutting the parts. The cutting speed was set properly to minimize the cut burrs that were needed to be removed manually.

- Precision bending the parts. Seamless alignment of the three bent up sides required high precision laser cutting as well as bending.