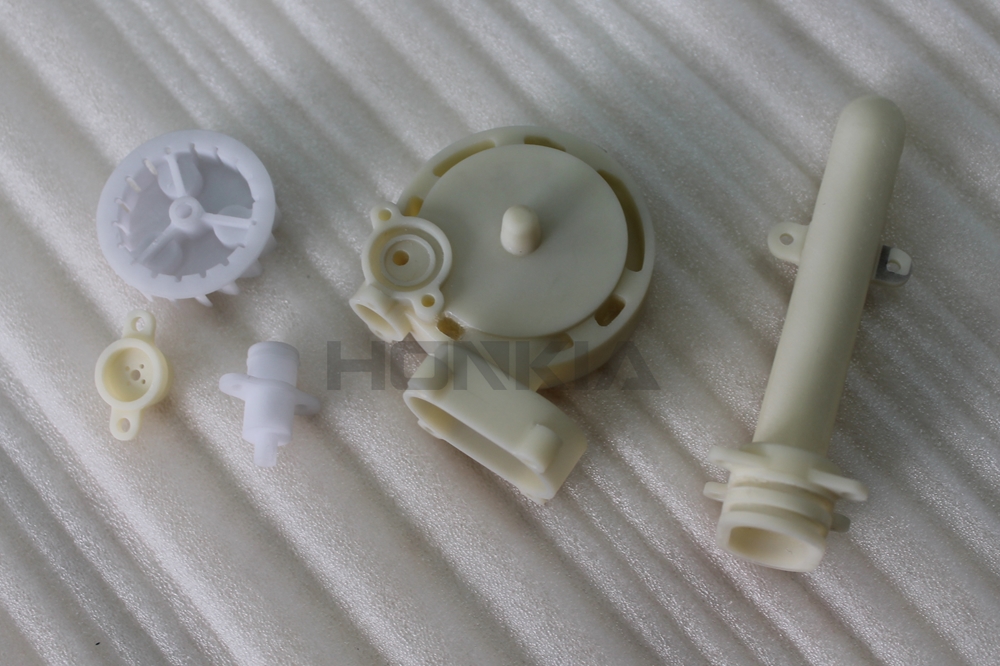

Rapid Product Prototype Manufacturing

Project Overview:Rapid Prototyping Process: CNC Machining

Prototyping Material: ABS, Polyoxymethylene (POM)

Surface Finishing: Painting, Polishing, Chrome Plating, Silk-screening

Quantity: 1 Piece

Lead Time: 7 Days

Customer specialized in developing kitchenware products in Chongqing, China. This prototype was made for presentation in exhibition to show new product developed. Customer had high expectation to the prototype that had to work and look like the product as close as possible.