CNC Titanium TI6AL4V Milled Parts

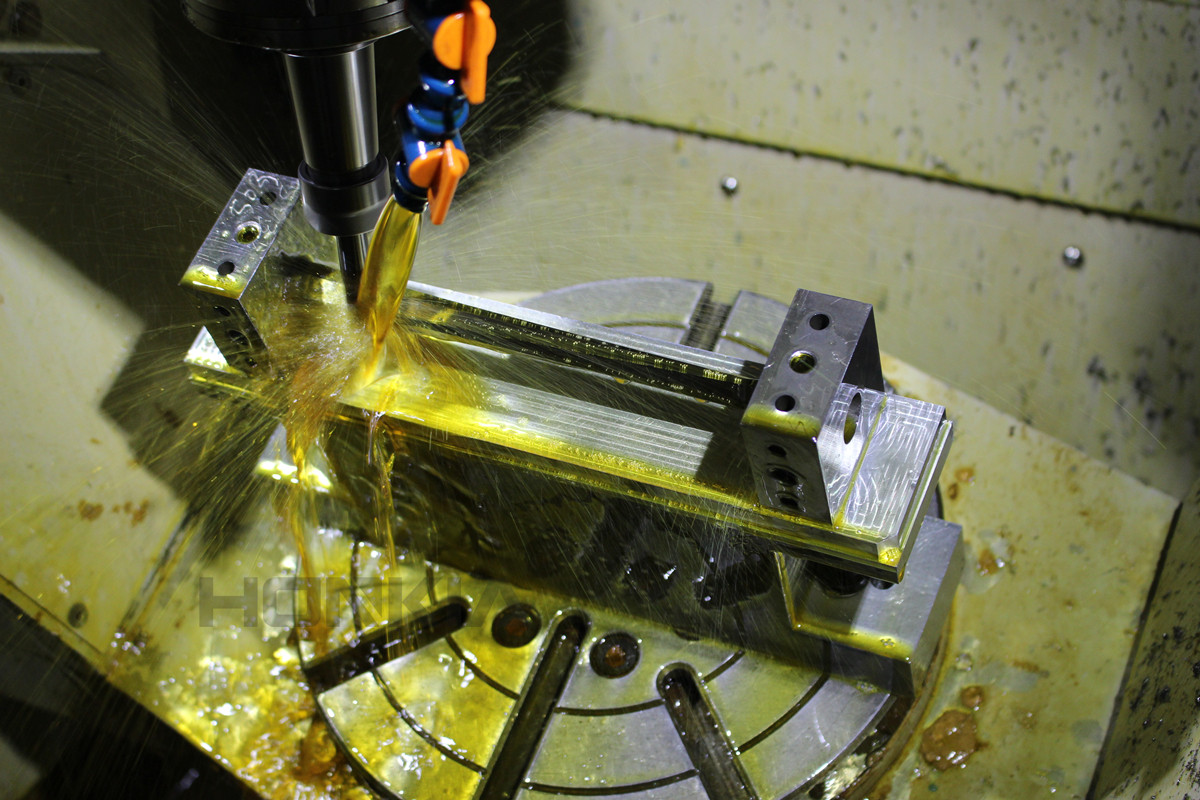

Project Overview: Titanium alloy had fairly low thermal conductivity that probably resulted in burning or chip adhesion to the cutting tool during milling.

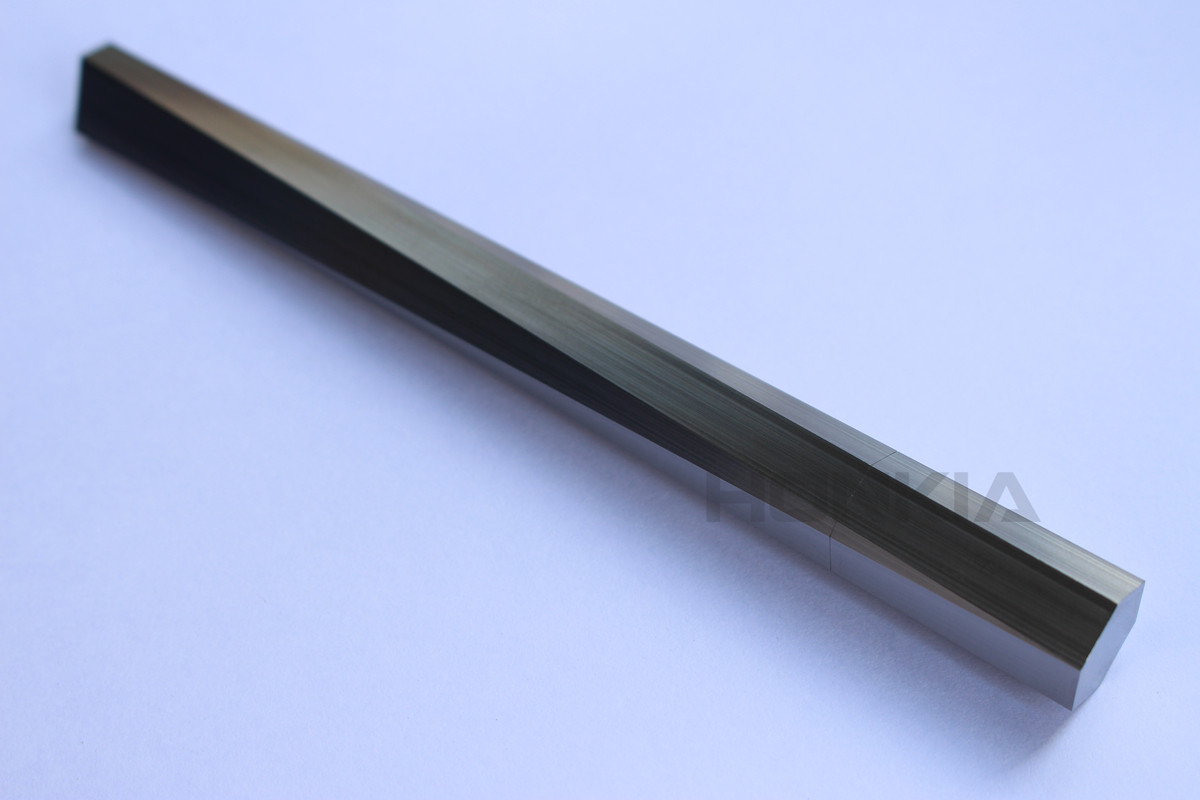

Titanium alloy had fairly low thermal conductivity that probably resulted in burning or chip adhesion to the cutting tool during milling. Seamless alignment between Cap and Housing was the key challenge, we offered minor but crucial design modification to meet this demand.

Seamless alignment between Cap and Housing was the key challenge, we offered minor but crucial design modification to meet this demand.