5 Axis CNC Machined Parts

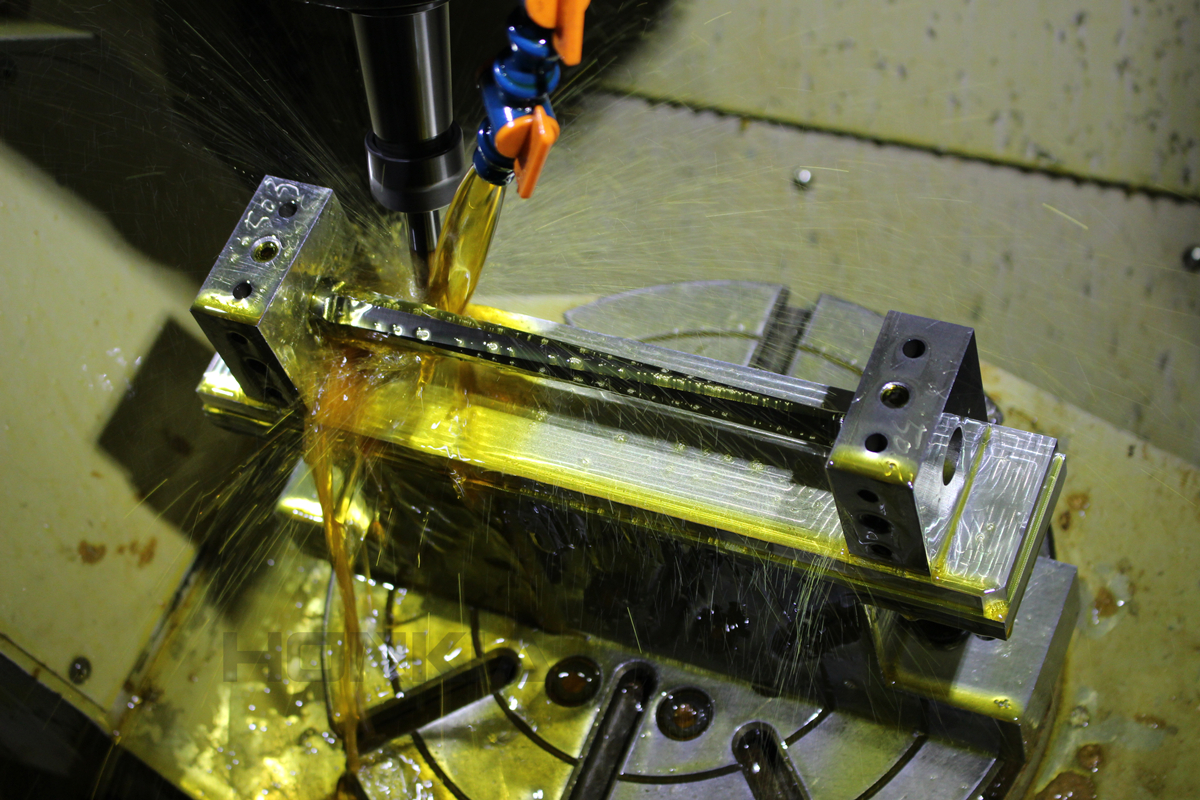

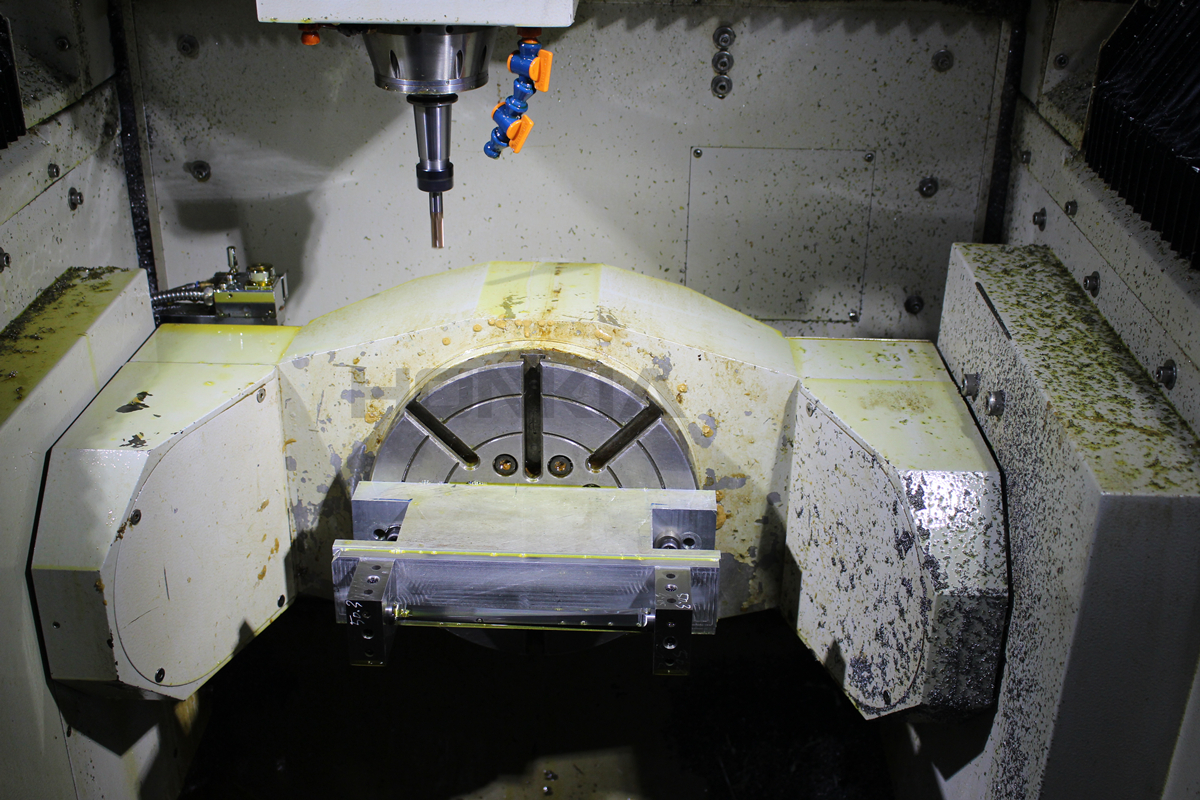

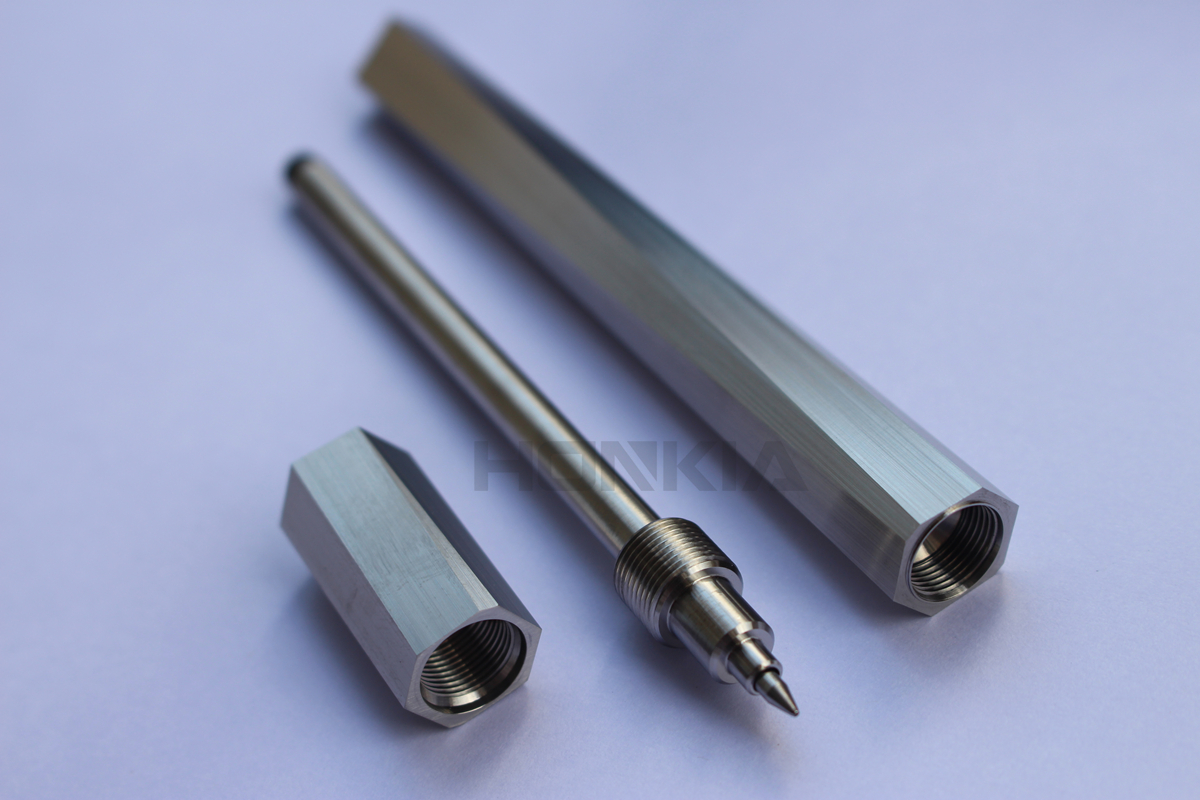

Project Overview:Manufacturing Process: 5 Axis CNC Machining

Machining Tolerance: ± 0.02 mm

Max. Machining Size: 500 × 280 × 260 mm

Lead Time and MOQ: Usually 7 Days, 1 Piece

Demonstration Material: Titanium Alloy TI6AL4V

5 Axis CNC was a high efficient milling process that the cutting tool moved across X, Y, Z linear axis and simultaneously rotated around A and B axis, it milled up to 5 sides (usually 6 sides a part) in a single setup.