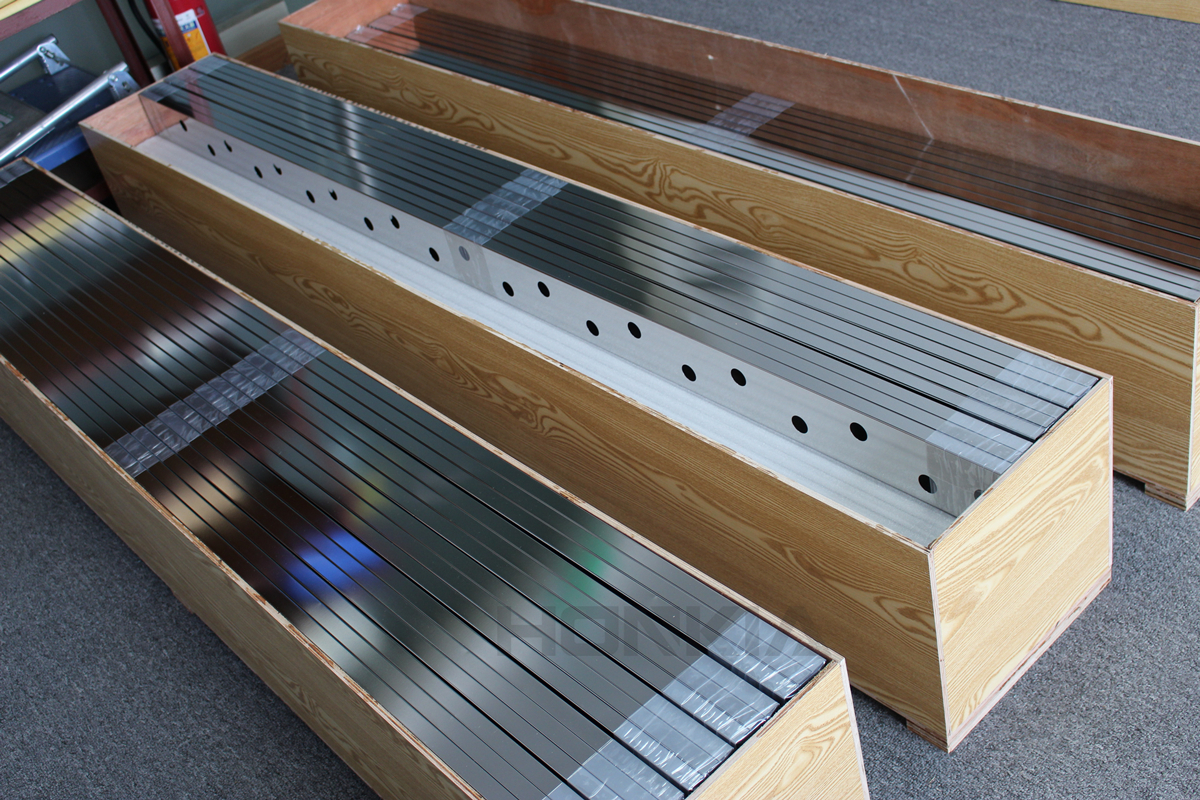

Electropolished Stainless Steel Parts

Project Overview:

Material: Stainless Steel 316 (SS 316)

Dimensions: 2091 × 95 × 19 mm (Thickness: 0.5 mm)

Surface Finishing: Deburring, Electropolishing

Manufacturing Process: Laser Cutting & Bending

Quantity & Lead Time: 510 Units, 15 Days

Electropolishing brought two benefits, one was glossy appearance by minimizing surface stains or minor scratches, another was corrosion resistance by eliminating surface blemishes to prevent moisture leading to corrosion. It also improved surface adhesion to other coatings.

- Laser cutting the stainless steel parts. Minimizing laser cut burrs was the first point to be considered during sheet metal fabrication.

- Precision bending the parts. The long length and thin thickness required more labor and high attention to bend this part precisely and quickly.