Reaction Injection Molded Enclosure Parts

Project Overview:Manufacturing Process: Reaction Injection Molding (RIM), M5 Insert

Molding Material: Polyurethane (PU Hei-Cast 8636-75)

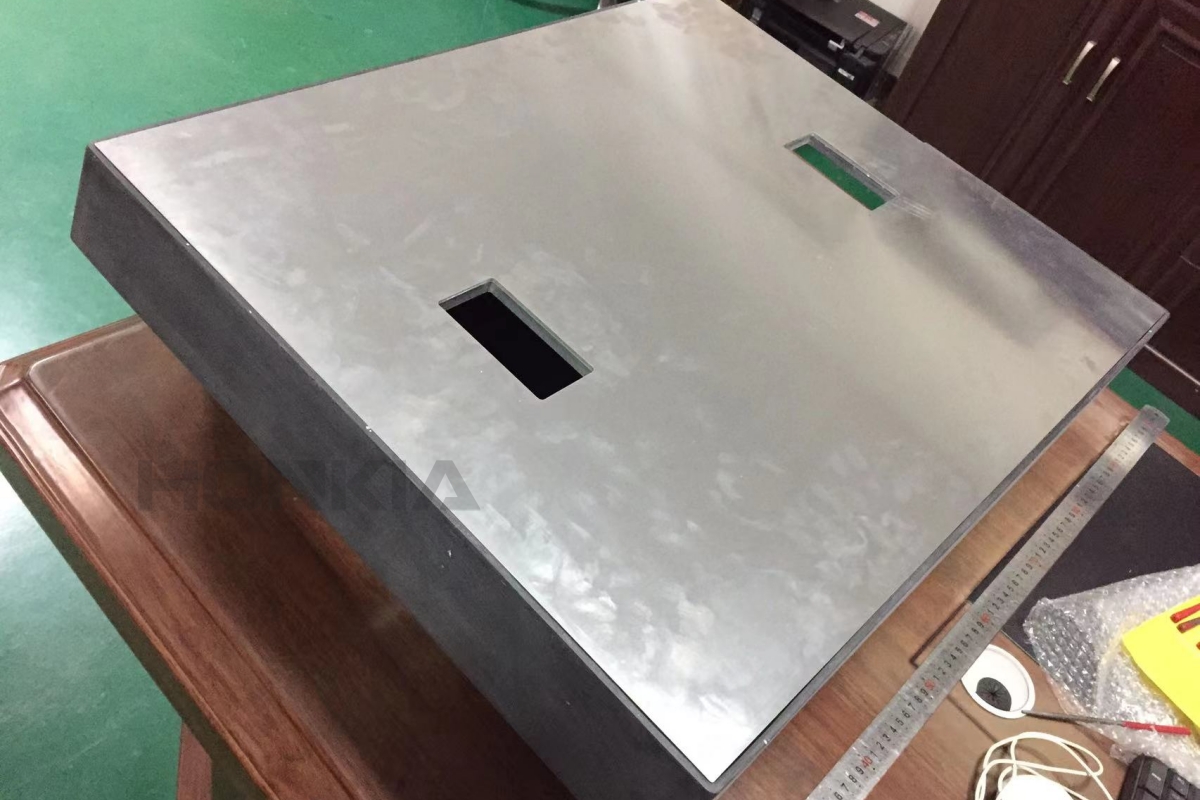

Part Dimensions: 675.7 × 562.4 × 211.8 mm (weight 5.65 KG)

Surface Finishing: Sanding, Texture and Conductive Painting

Quantity & Lead Time: 25 Units, 25 Days

The extremely competitive mold price and fast delivery of our RIM process got this big enclosure low volume manufactured cheaply and quickly. The finished enclosures had to not only perform as intended, but also look as close as possible to the reference sample provided by customer.

Our RIM mold cost just a fraction of its relative steel mold used for mass production, manufacturing time usually 2 weeks instead of several months.

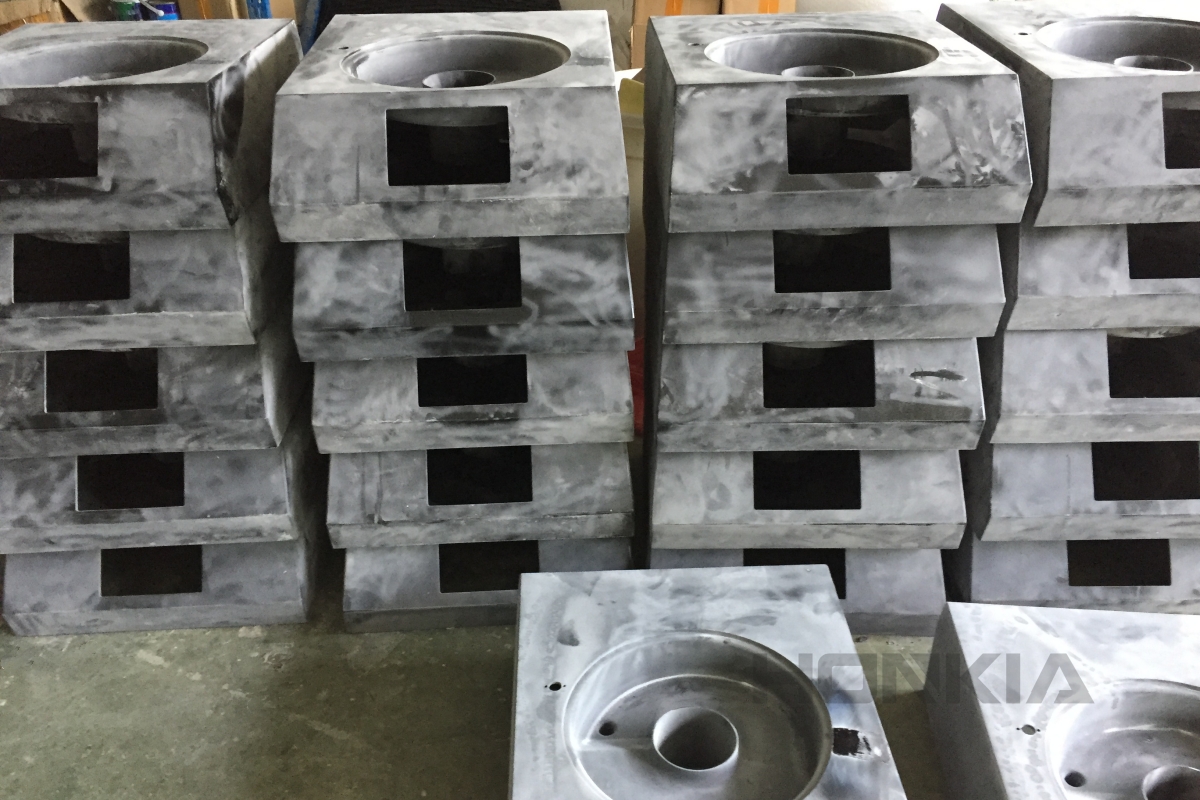

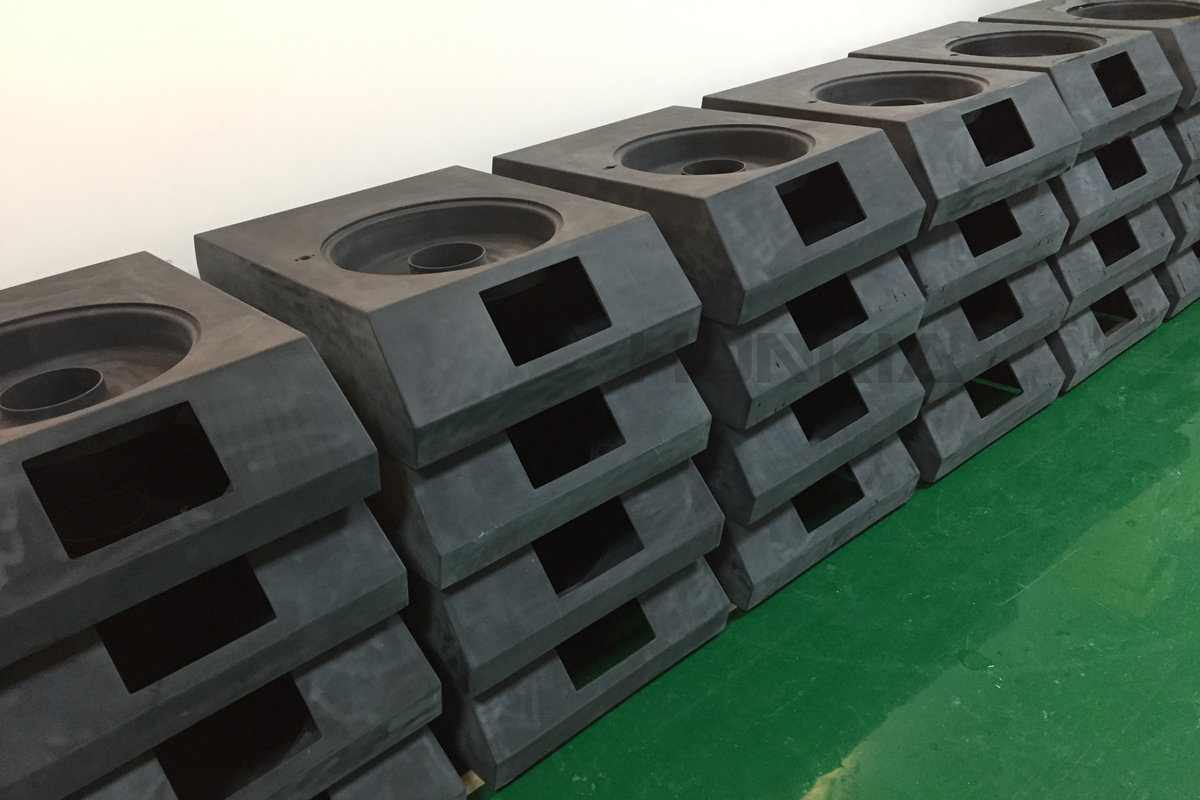

Our RIM mold cost just a fraction of its relative steel mold used for mass production, manufacturing time usually 2 weeks instead of several months. The reaction injection molded part prior to surface finishing. Good flexibility and high durability were the great features of our RIM parts.

The reaction injection molded part prior to surface finishing. Good flexibility and high durability were the great features of our RIM parts.