Reaction Injection Molding

Reaction Injection Molding (RIM) is a Cold and Low-Pressure casting process that specializes in low volume manufacturing large and complex-geometry parts quickly and economically. The most commonly used material is liquid bi-component polyurethane (PU) of polyol and isocyanate, when the two liquids are mixed together at certain amount ratio in mixing head, a chemical exothermic reaction begins to create polyurethane resin, then the mixture is quickly injected into mold cavity at low-pressure and room temperature to cast the parts.

At Honkia, our RIM molds are mostly made of epoxy resin and silicone rubber (sometimes aluminum), cost just a fraction (5%-10%) of the conventional steel molds used for mass production, mold manufacturing time takes usually two or three weeks instead of several months. So our RIM process brings cost and time savings as much as possible, and favors the innovative low volume projects under limited budget and pressing time.

The Cold and Low-Pressure injection molding allows for excellent tolerance and consistent geometry to our RIM parts though the molds are made of mainly plastic instead of rigid steel. The soft silicone rubber pieces will be freely replaced by fresh ones after usually 100 shots to achieve finally total 500-1000 shots, which also brings good flexibility in supply to meet market demands, without holding excessive stocks and long time waiting.

Good flexibility and durability are the great features of our RIM parts that play a crucial role in many industries and sectors, including medical, marine, transportation, construction, agriculture, telecommunication, etc. The parts can be sandblasted, painted in different colors and textures, silk-screened, insert molded and overmolded.

Though our Reaction Injection Molding works fine for different wall thicknesses, uniform wall thickness and proper draft angle are still recommended during part design to achieve improved quality, consistency and efficiency. We look forward to doing more and better through our continuously improving RIM expertise and experience.

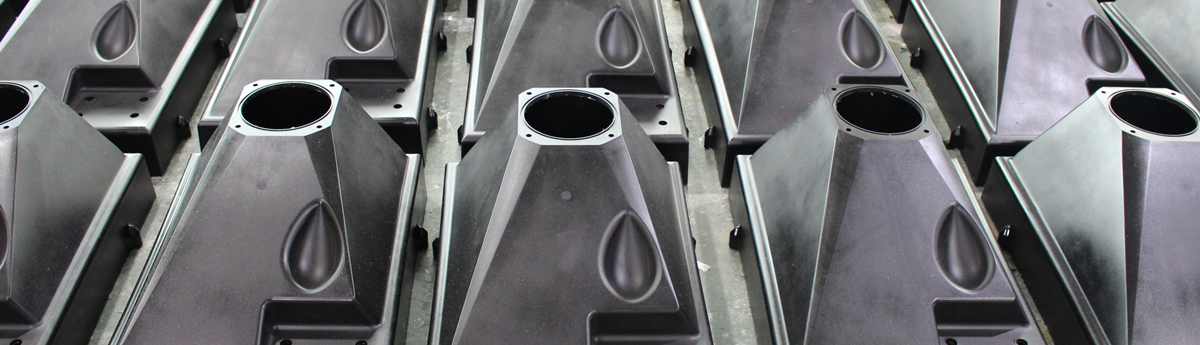

Reaction Injection Molded Enclosure Parts

Reaction Injection Molded Enclosure Parts Rapid Low Volume Aluminum Prototypes

Rapid Low Volume Aluminum Prototypes