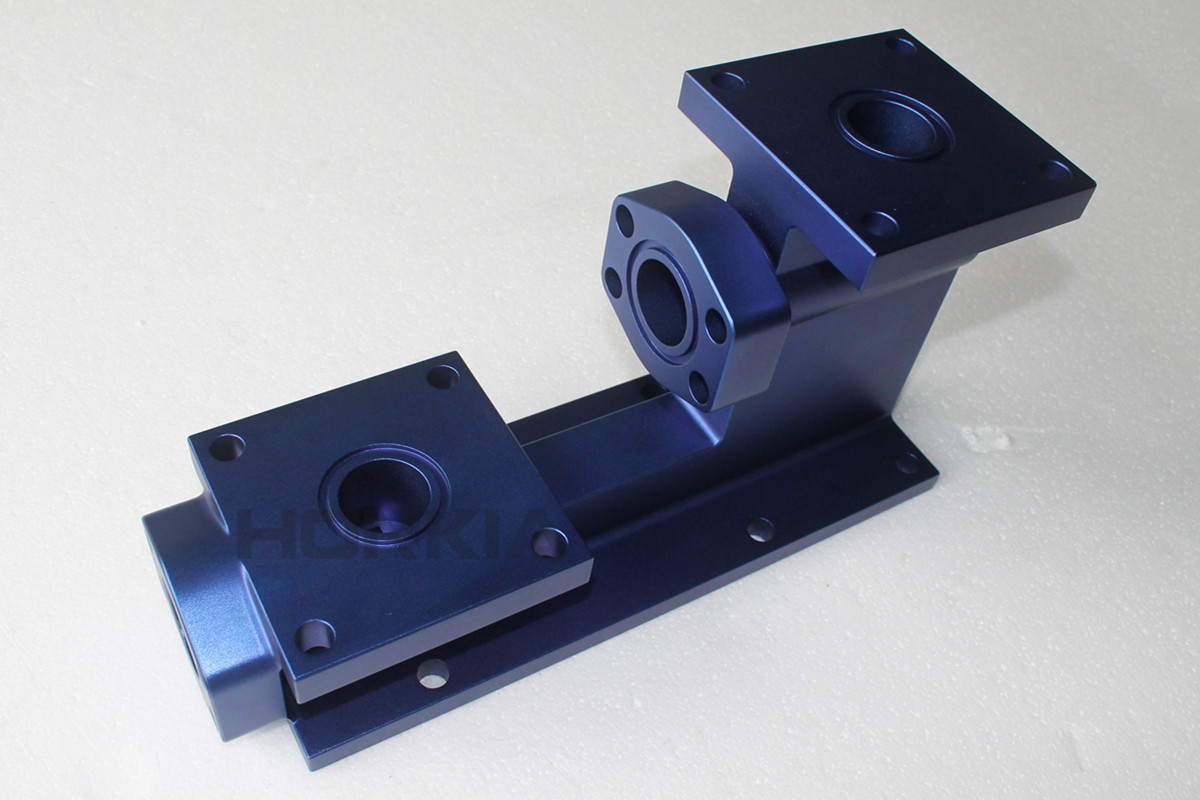

Aluminum Machined and Anodized Prototype

Project Overview:Manufacturing Process: CNC Machining

Material: Aluminum 6061-T6

Part Dimensions: 390.00 × 213.00 × 130.00 mm

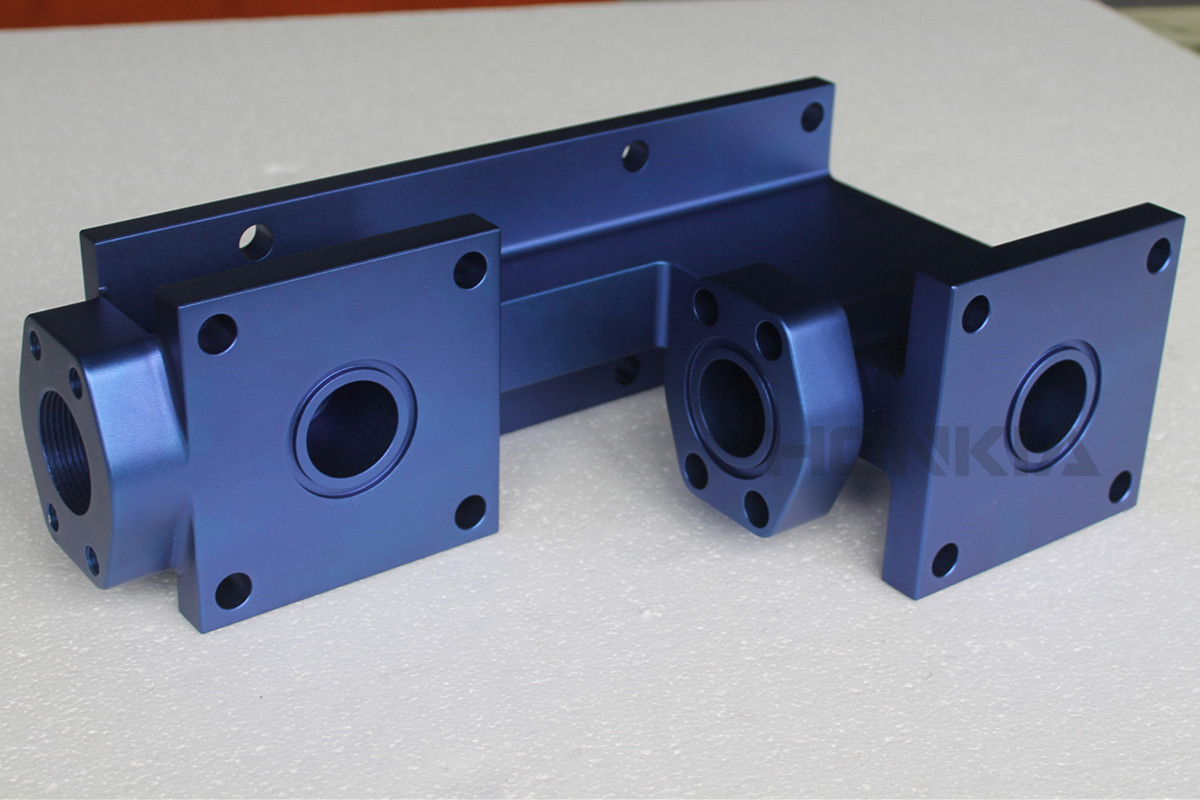

Surface Finishing: Sanding, Threading, Anodizing Blue

Quantity and Lead Time: 1 Unit, 7 Days

Customer was an Australia company offering professional service and engineered solutions for fluid systems. This prototype was made to test liquid pressure and fitting before low volume production. Since big dimensions, geometry stability and milling tolerance were key points.

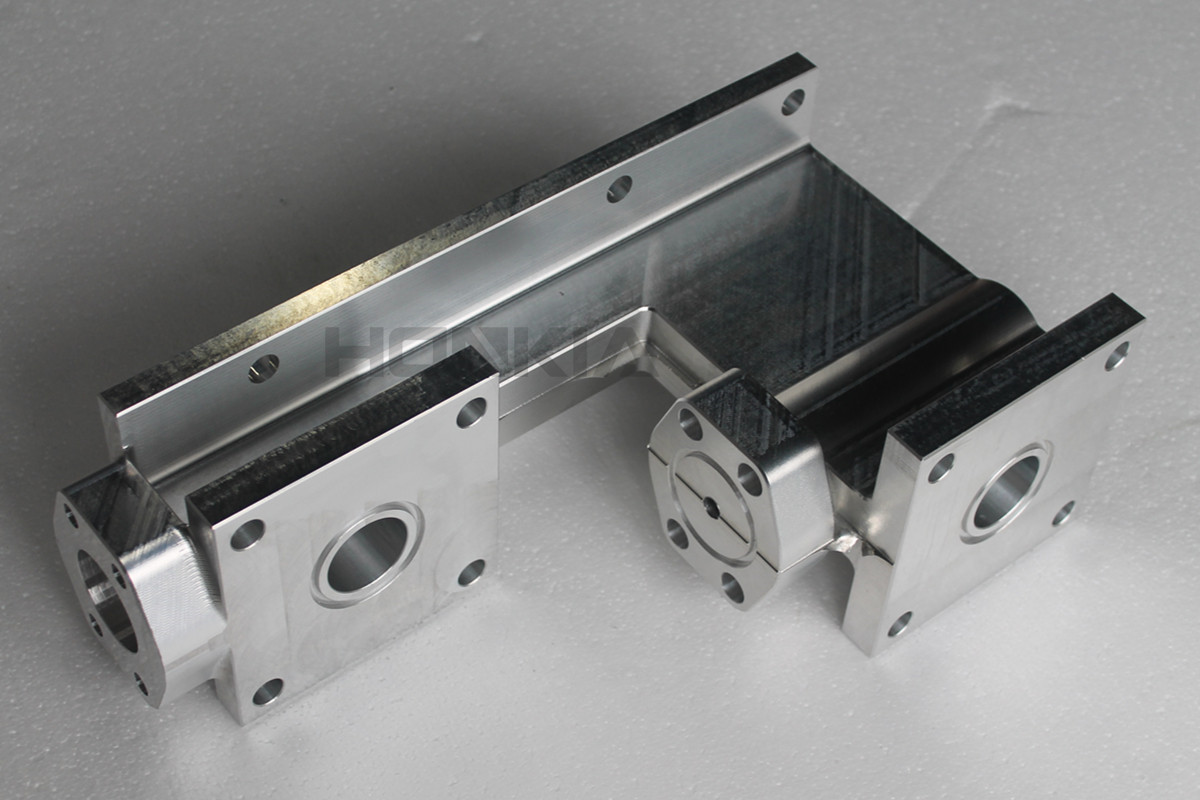

CNC machining usually started from coarse milling with big cutting tools to fast remove unwanted material, to gradually fine milling by smaller tools.

CNC machining usually started from coarse milling with big cutting tools to fast remove unwanted material, to gradually fine milling by smaller tools. For 3 axis CNC milling, workpiece was rotated manually and repositioned accurately to mill the part side by side, tolerance around ± 0.1 mm.

For 3 axis CNC milling, workpiece was rotated manually and repositioned accurately to mill the part side by side, tolerance around ± 0.1 mm.