ABS Milled and Chrome Plated Prototypes

Project Overview:

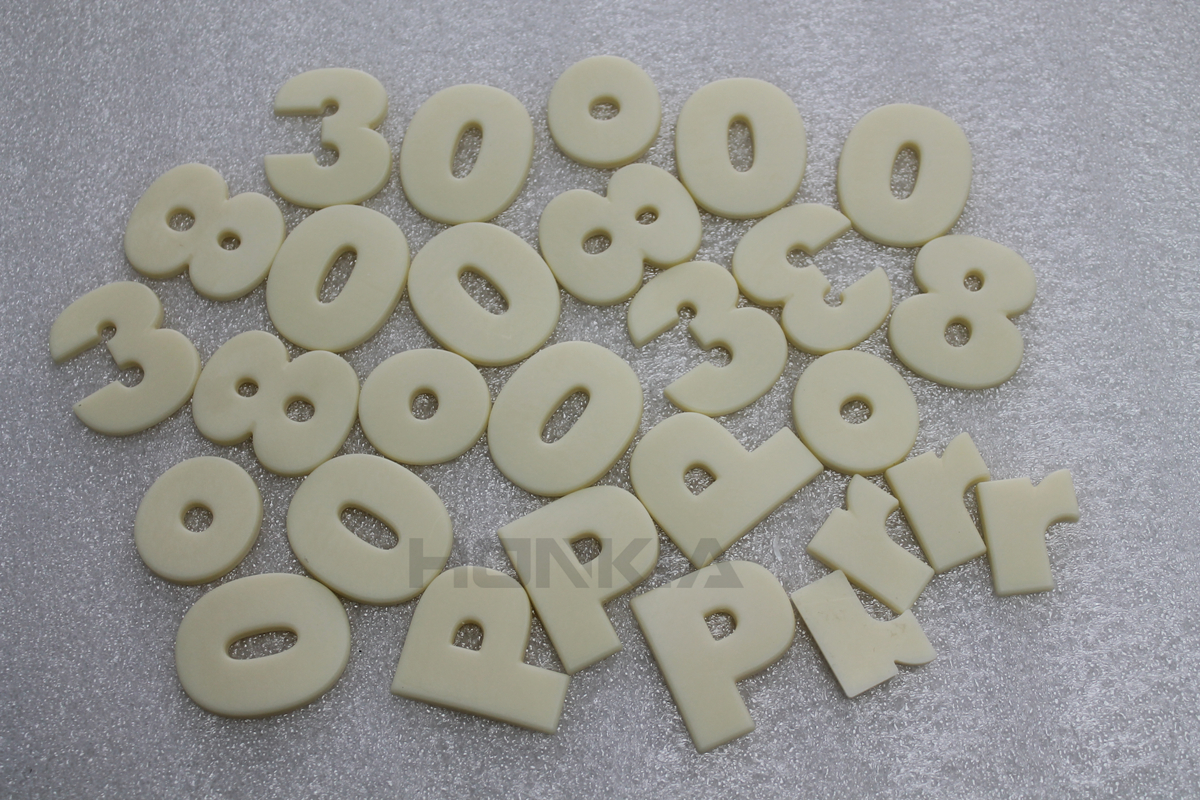

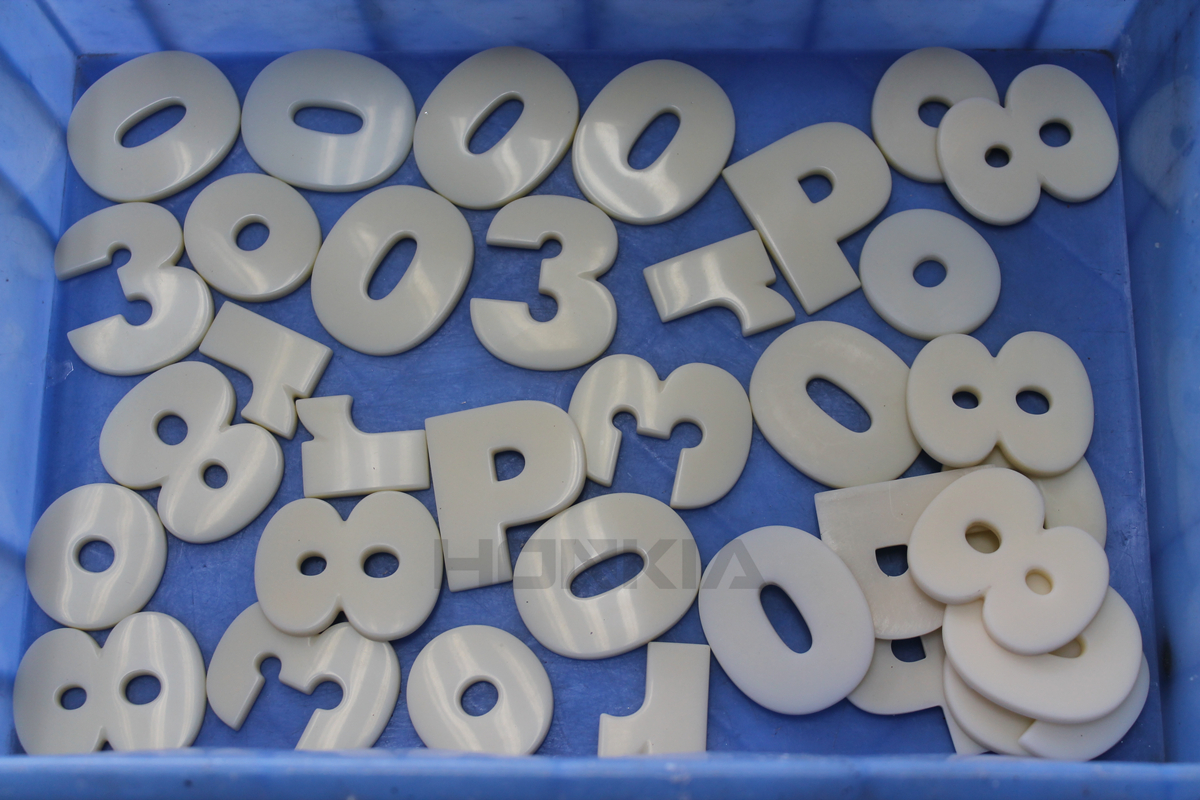

Rapid Prototyping Process: CNC Machining

Prototype Material: ABS

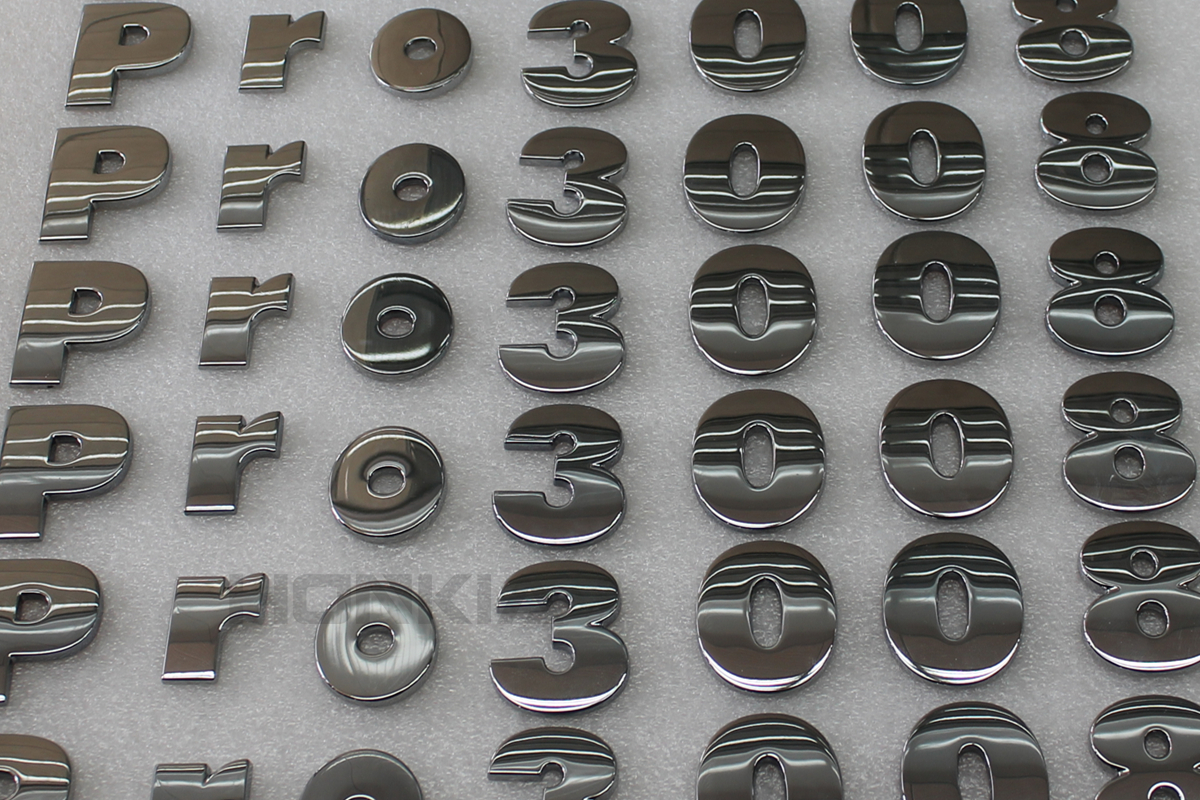

Surface Finishing: Sanding, Mirror Polishing, Chrome Plating

Quantity: 8 sets of totally 56 pcs

Lead Time: 5 Days

This was an urgent project from an engineering design company in New Delhi, India. Customer requested to have prototypes on his hands within 7 days including shipping before our upcoming CNY holidays. We worked intensively to finish this order in time without compromise of quality.