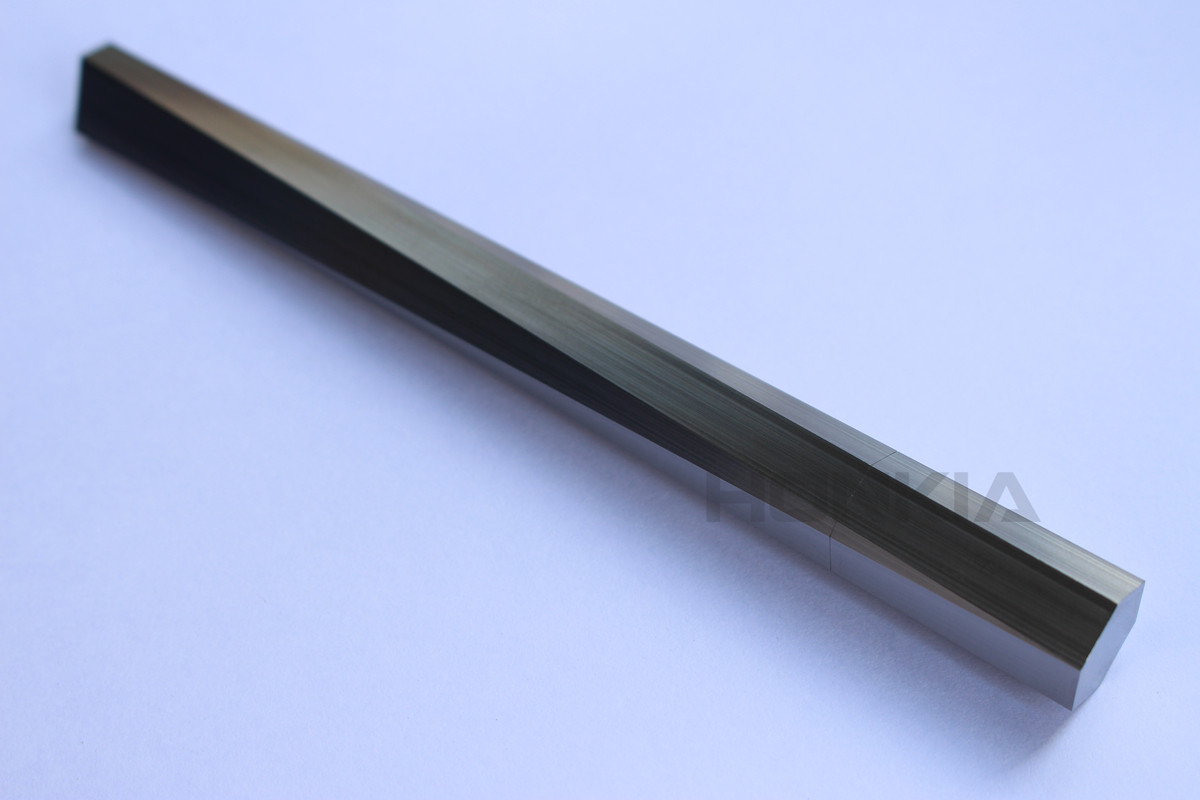

CNC Titanium TI6AL4V Milled Parts

Project Overview:Material: Grade 5 Titanium Alloy TI6AL4V

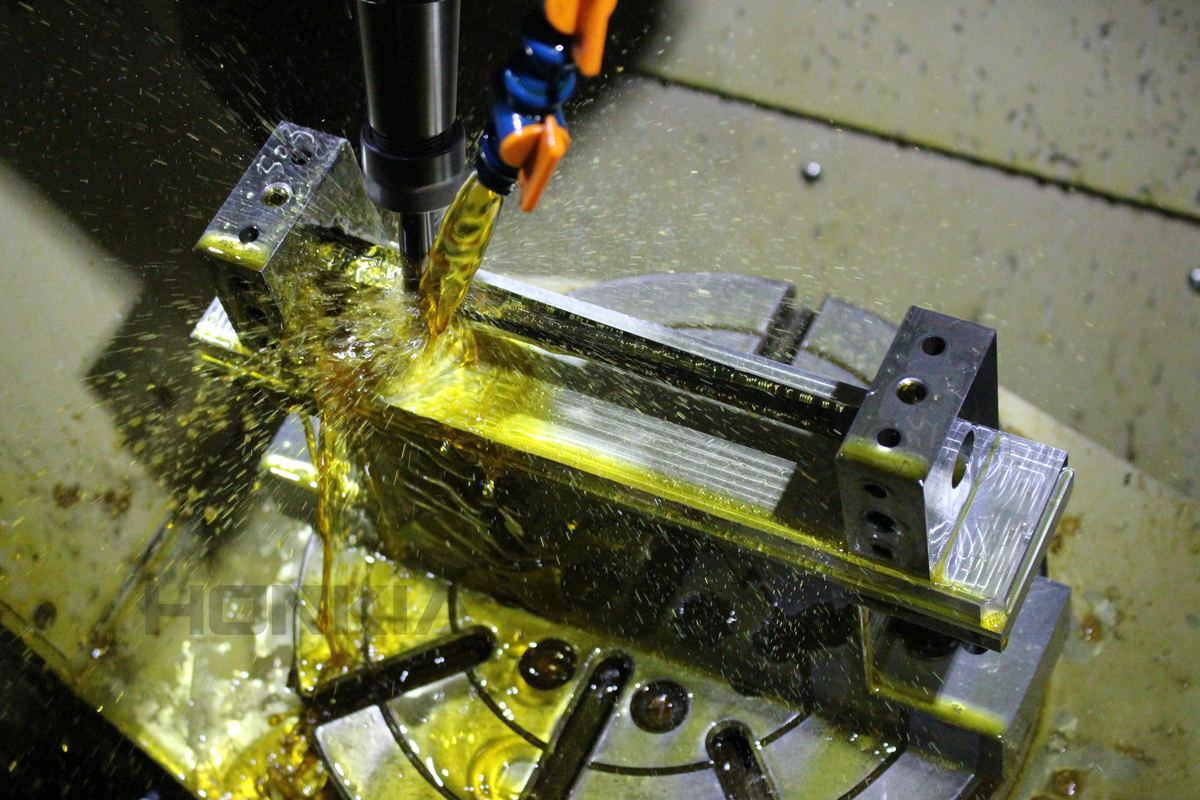

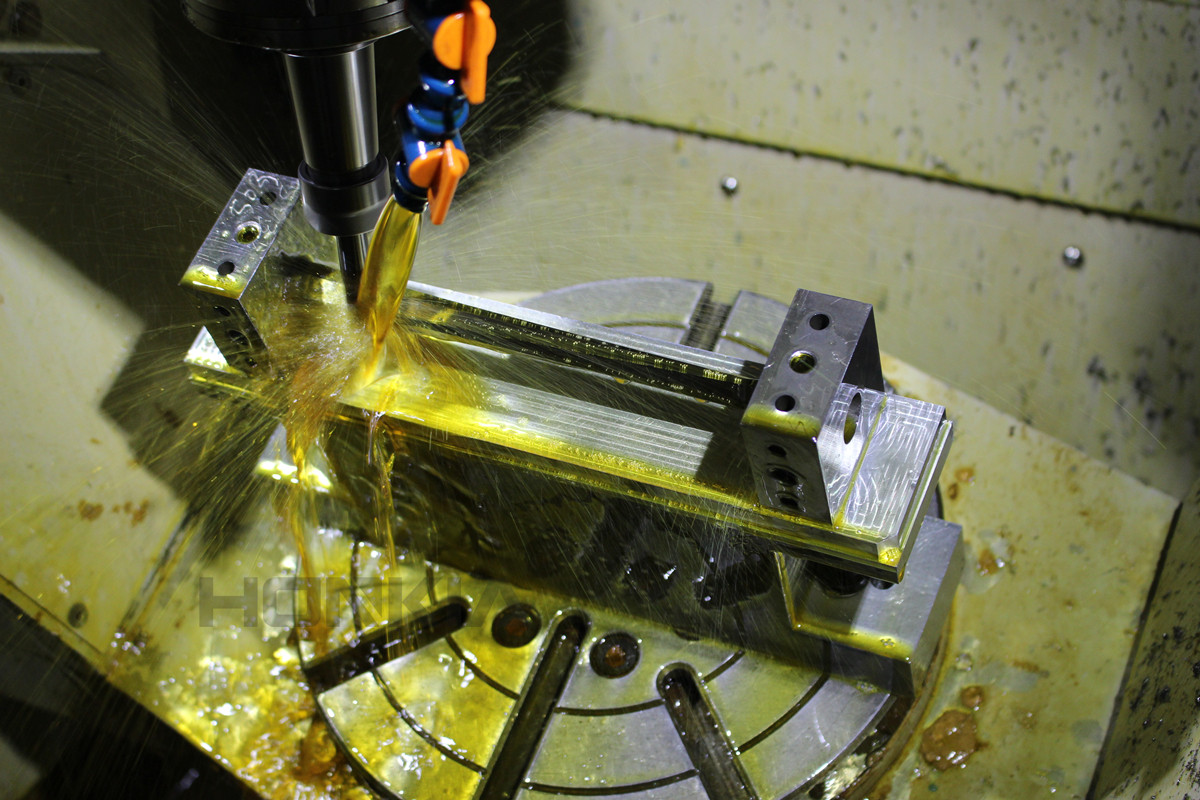

Manufacturing Process: CNC Machining, Turning, Wire Cutting

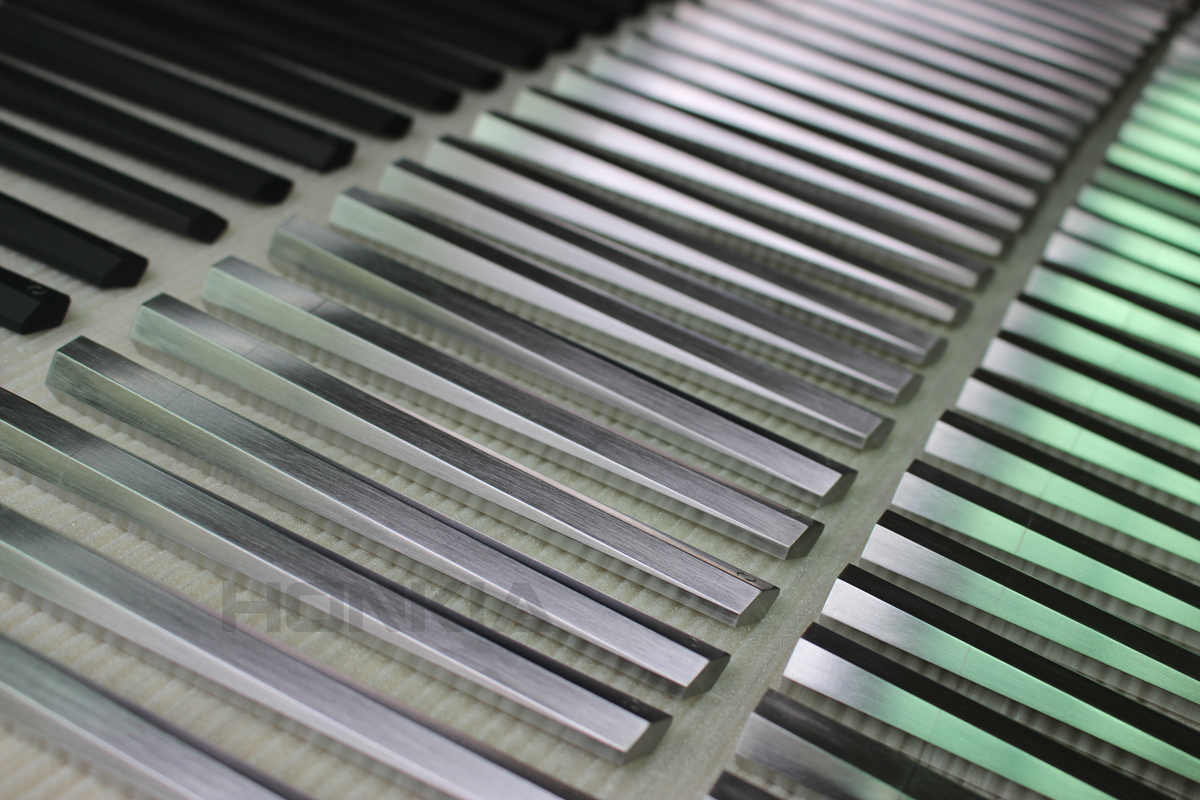

Surface Finishing: Beadblasting, Brushing, PVD Coating, Laser Engraving

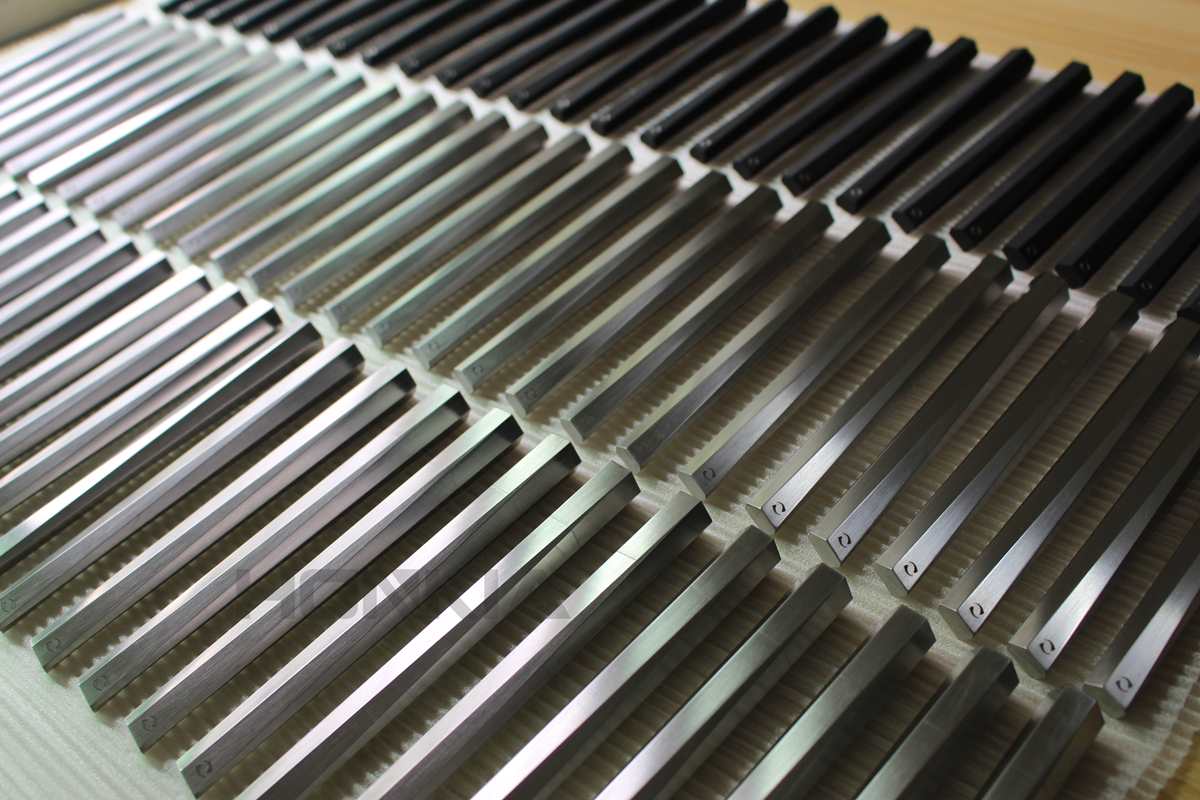

Quantity: 100 Units (30 Units PVD Coated, 70 Units Brushed)

Lead Time: 20 Days

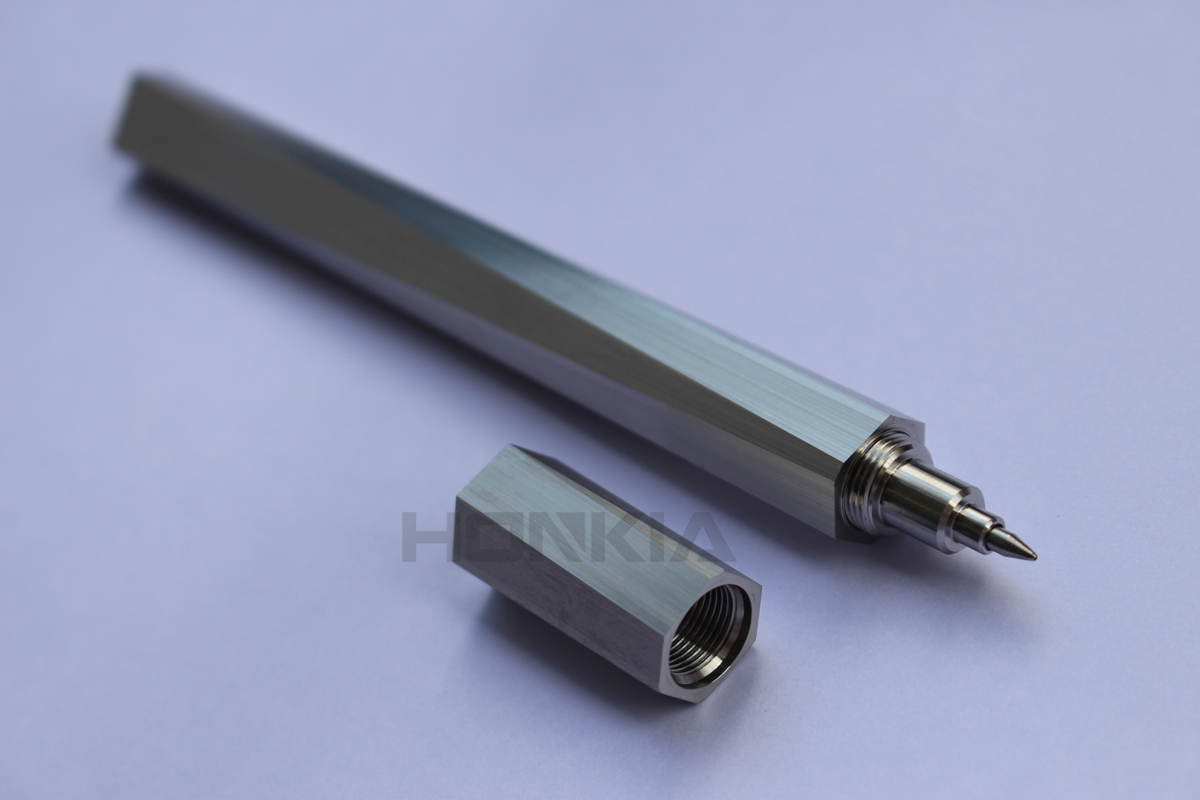

To get high quality, lightweight, durability for this Pen, customer changed aluminum and stainless steel to grade 5 titanium alloy TI6AL4V for its properties of high strength-to-density ratio and better corrosion resistance.

Titanium alloy had fairly low thermal conductivity that probably resulted in burning or chip adhesion to the cutting tool during milling.

Titanium alloy had fairly low thermal conductivity that probably resulted in burning or chip adhesion to the cutting tool during milling. Seamless alignment between Cap and Housing was the key challenge, we offered minor but crucial design modification to meet this demand.

Seamless alignment between Cap and Housing was the key challenge, we offered minor but crucial design modification to meet this demand.