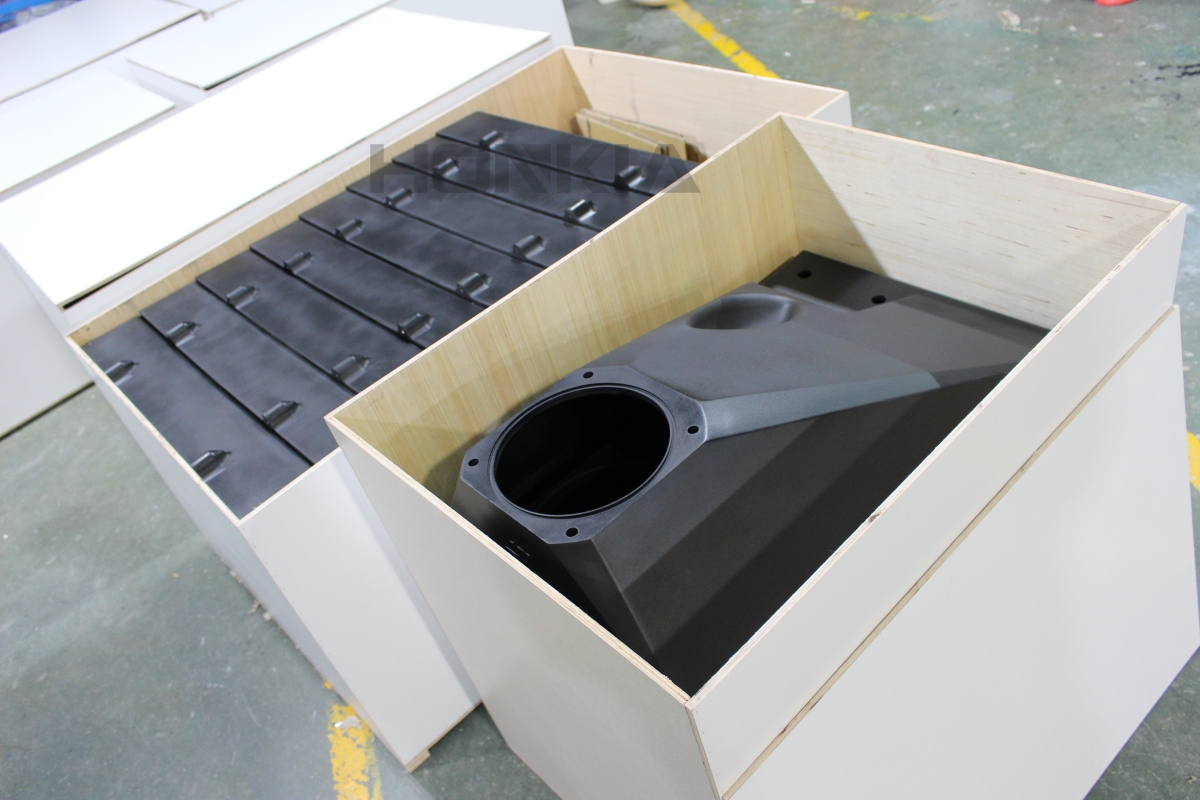

Reaction Injection Molding Large Parts

Project Overview:Manufacturing Process: Reaction Injection Molding (RIM), M6 Insert

Molding Material: Polyurethane PU (Hei-Cast 8636-75)

Tooling Material: Epoxy Resin, Silicone Rubber, Steel

Part Dimensions: 743 × 512 × 315 mm (thickness: 5/7/10/20 mm)

Quantity & Lead Time: 60 Units, 25 Days

This Engine Casing was originally manufactured by sheet metal fabrication with lots of bending and welding. To save production cost well, customer modified part design to have it Reaction Injection Molded. No shrink marks on the molded parts though thick and various wall thicknesses.

The silicone rubber pieces of our RIM mold would be free replaced by fresh ones after usually 100 shots to get finally total 500-1000 shots.

The silicone rubber pieces of our RIM mold would be free replaced by fresh ones after usually 100 shots to get finally total 500-1000 shots. Since the unique injection molding system, our RIM process worked fine for manufacturing the large and heavy parts with various wall thicknesses.

Since the unique injection molding system, our RIM process worked fine for manufacturing the large and heavy parts with various wall thicknesses.