Both CNC machining and SLA are great rapid prototyping techniques that are widely used in nearly all walks of life today, each of them has the big and different advantages for custom manufacturing. Here is some information for the readers to help learn more about them and select the proper technique when possible.

Material Options: All hard plastic and metal materials are available for CNC machining; SLA materials are limited to liquid photosensitive polymer resins with similar properties to real engineering plastics ABS, PC and PP when they cured and solidified.

Manufacturing Tolerance: In general, CNC machining tolerance is ± 0.1/100 mm, its X and Y direction tolerances are tighter than Z direction; SLA tolerance is almost same as CNC also at ± 0.1/100 mm. In Z direction tolerance, CNC is relatively higher than SLA.

|

|

|

Part Surface: SLA part is built layer by layer with layer thickness typically 0.1 mm and the excess cured polymer resin will adhere to the part surface, which result in the rough part surface (particularly in Z direction). CNC part is made by gradually cutting away the unwanted material from a block of raw material, it is easy to control the machined surface quality. Thus, CNC part surface could be smoother than SLA one.

Part Durability: CNC part is made out of hard plastic and metal materials. SLA part is built by liquid photosensitive polymers with similar material properties to the real engineering plastics, thus CNC part is more durable than SLA one.

|

|

|

|

Manufacturing Time: The manufacturing time mainly depends on the part size and design. The biggest advantage of SLA is the free design limitation compared to CNC machining, but for the part of simple design and big volume, its CNC machining time could be shorter than SLA. Which means SLA has time advantage for complex design, and CNC has time advantage for simple design and big volume.

|

|

|

Production Cost: The expensive SLA materials around $600/KG takes majority of SLA part cost, common CNC materials cost $3-10/KG, and CNC part cost mainly depends on its machining time. Considering the part design and volume, SLA cost will be competitive for the part of complex design and small volume, and CNC cost will be cheaper for the part with simple design and big volume.

We could see that the selection of CNC machining or SLA rapid prototyping for custom part manufacturing depends on the part material, design, size, tolerance and strength requirements, each of them has their respective manufacturing advantages and disadvantages.Here at Honkia Prototype, we can help customers to choose the best process for their projects acording to the specified prototyping or manufacturing requirments.

Reaction Injection Molded Enclosure Parts

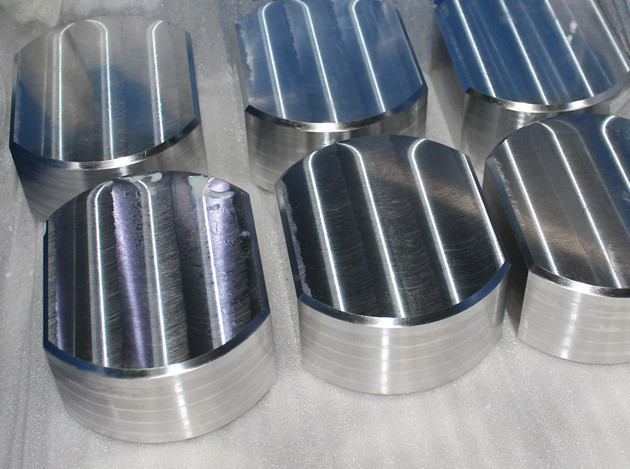

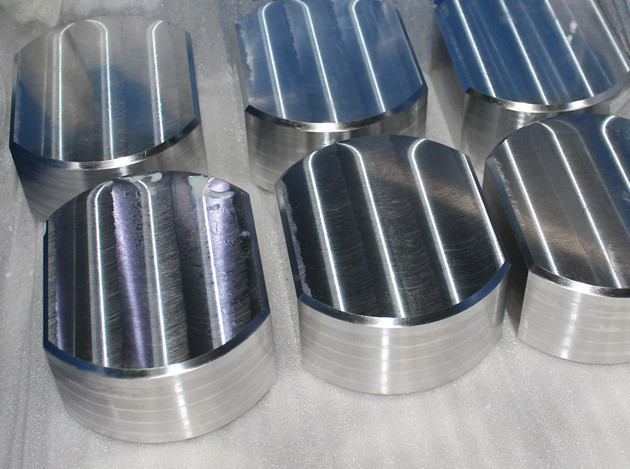

Reaction Injection Molded Enclosure Parts Rapid Low Volume Aluminum Prototypes

Rapid Low Volume Aluminum Prototypes