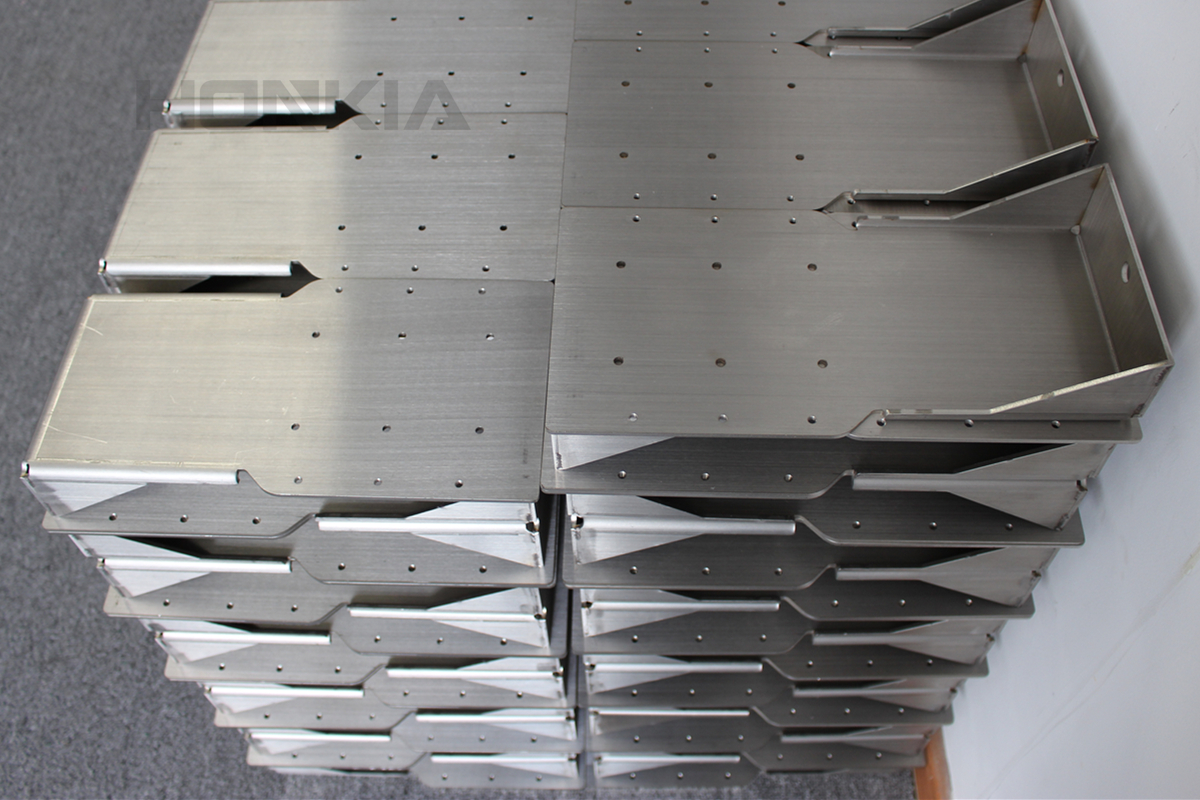

Sheet metal can be cut, bent, and stretched into a nearly any desired shape. Material removal processes can create holes and cutouts in any 2D geometric shape. Deformation processes can bend the sheet numerous times to different angles or stretch the sheet to create complex contours. The size of sheet metal parts can range from a small washer or bracket, to midsize enclosures for home appliances, to large airplane wings. These parts are found in a variety of industries, such as aircraft, automotive, construction, consumer products and furniture.

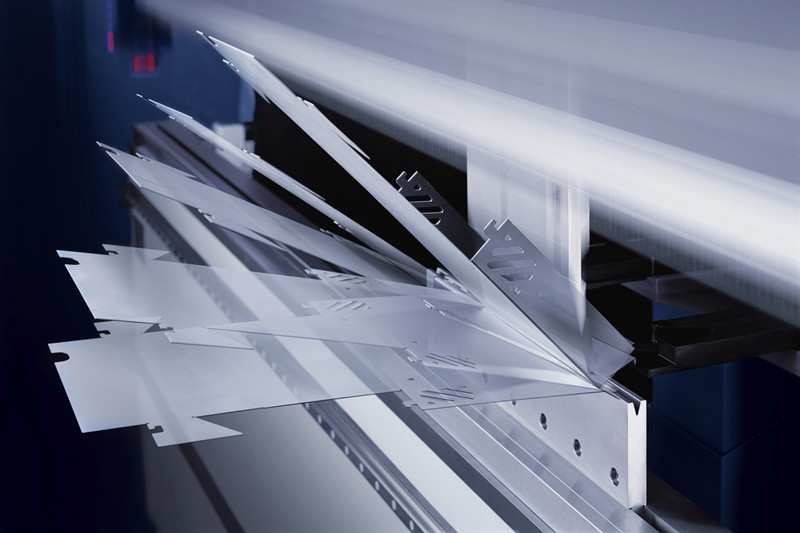

Sheet metal fabrication processes can mostly be placed into two categories - forming and cutting. Forming processes are those in which the applied force causes the material to plastically deform, but not to fail. Such processes are able to bend or stretch the sheet into the desired shape. Cutting processes are those in which the applied force causes the material to fail and separate, allowing the material to be cut or removed. Most cutting processes are performed by applying a great enough shearing force to separate the material, and are therefore sometimes referred to as shearing processes. Other cutting processes remove material by using heat or abrasion, instead of shearing forces.