Rapid Tooling & Plastic Injection Molded Parts

Project Overview:

Manufacturing Process: Rapid Tooling & Plastic Injection Molding

Tooling Material: Mold Steel NAK 80

Molding Material: Fire Retardant PC+ABS

Quantity: 1000 Units

Lead Time: 25 Days

Customer was an America based company specializing in developing innovative products in home appliance. Considering quantity, consistent quality, rapid tooling and injection molding was the ideal process. We offered suggestions to improve fitting and reduce manufacturing cost.

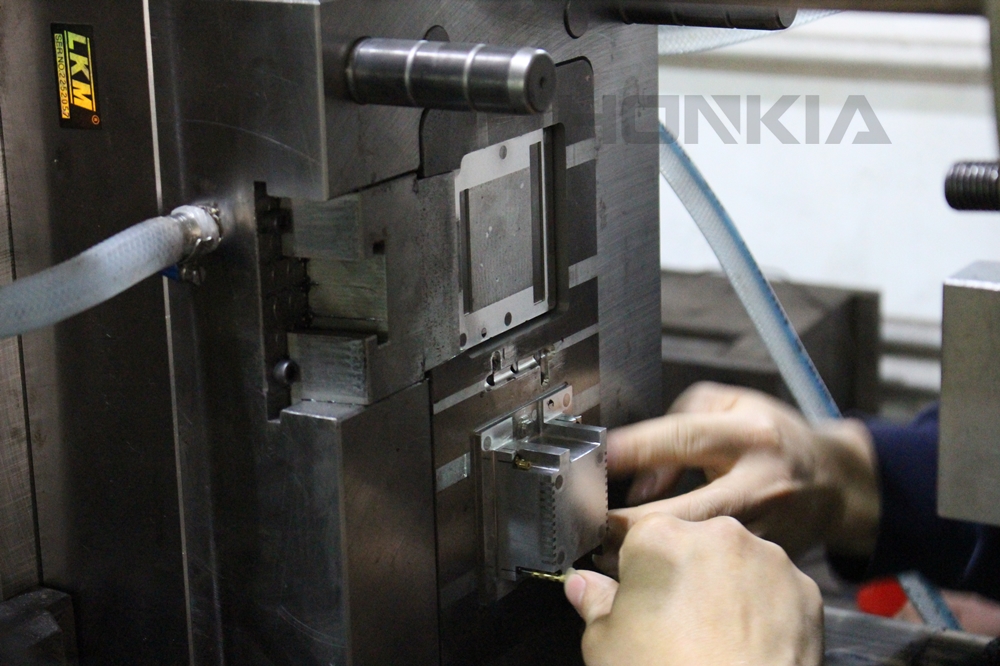

Electrical Discharge Machining (EDM) the tooling core. EDM was usually used to make the CNC milled round corners to straight or sharp ones.

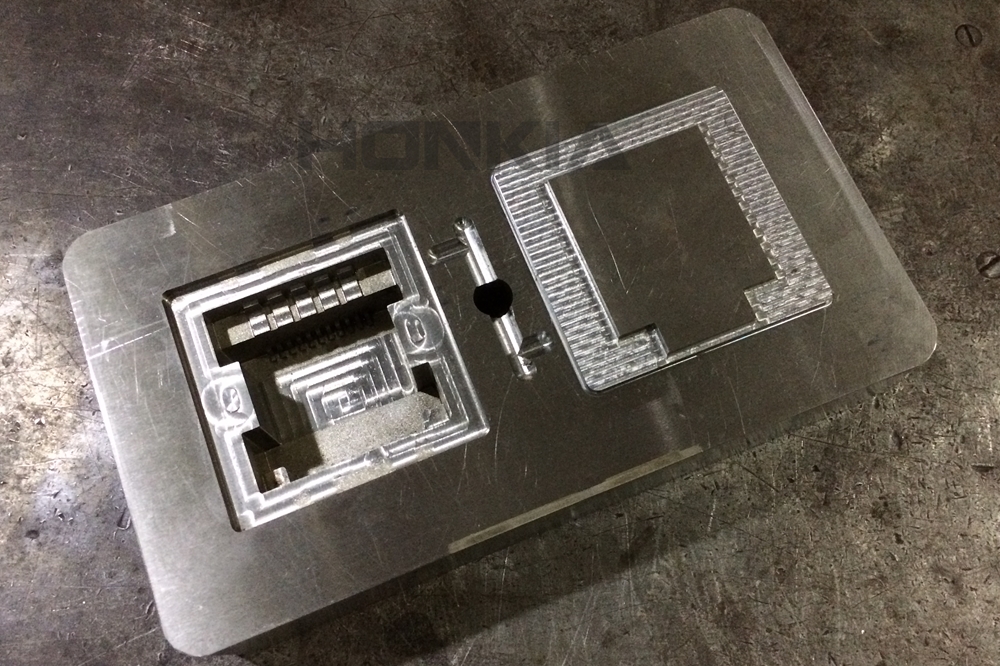

Electrical Discharge Machining (EDM) the tooling core. EDM was usually used to make the CNC milled round corners to straight or sharp ones. To save production cost and time, we usually had parts as more as possible in one mold without the compromise of injection molded quality.

To save production cost and time, we usually had parts as more as possible in one mold without the compromise of injection molded quality. The finished tooling for production. Customer was new to injection molding, we offered free and necessary design optimizations for improved quality.

The finished tooling for production. Customer was new to injection molding, we offered free and necessary design optimizations for improved quality. The injection molded parts. Part to be injection molded had to be designed well to facilitate its production for low cost and better fitting & appearance.

The injection molded parts. Part to be injection molded had to be designed well to facilitate its production for low cost and better fitting & appearance.